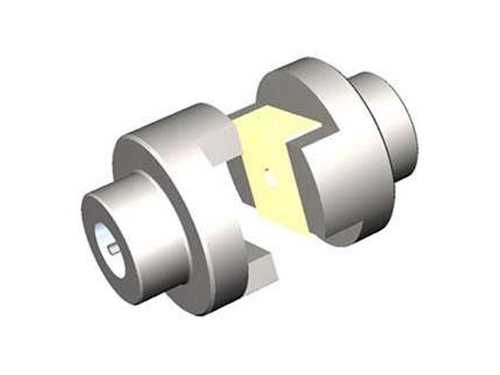

Coupling alignment method and device measures

Published: 2019-12-23

Published: 2019-12-23Coupling manufacturersTo introduce to you,CouplingThe four steps of the alignment method:

1.CouplingRadial alignment

CouplingThe timing should be adjusted vertically first.Using the three-point inspection data, the thickness of the front and rear gaskets can be calculated, and the offset of the two axes can be detected.The diameter of the outer edge of the movable end coupling plus the distance from the outer edge of the coupling to the center of the axial kilometer rod hole; the distance from the end face of the movable end coupling to the center of the front foot bolt of the movable end; and the center of the front foot bolt The distance from the back foot of the movable end.Based on the above data, the thickness of the front and rear gaskets can be known.If the motor is higher than the fixed end, the shim should be reduced; if the motor is lower than the fixed end, the shim should be increased.

After adjusting the vertical direction, the detection data of each point changes. The data of 1 points and 2 points of 3 point should be measured again, and the data of 2 points and 3 points should be measured again.After adjustment, just check whether it is within the allowable error range.

2.CouplingPrinciple revision

The projection of the end face circle of the moving end of the motor on the fixed end face is approximately a perfect circle, because the distance from the center of the moving end to the end face of the fixed end remains unchanged.If you want to meet at the same time, the moving end axis and the fixed end axis are on the same line, but ideally normal.When the actual correction time is in place, first set the allowable error. When the error generated by the correction time is within the allowable error range, the correct error ends.In many cases, the lower detection point of the pump cannot be detected and cannot perform correct work.

3. The correct steps of the three-point table typing method

(1) The fixed magnetic mount, the measuring rod and the kilometer are respectively placed on the coupling of the fixed end and the movable end;

(2) Turn the axis to the 1 o'clock position, and clear the two-thousand-meter indicator respectively;

(3) Turn the axis to the 2 o'clock position and read out the data;

(4) Turn the axis to the 3 o'clock position and read out the data;

(5) Calculate separately

(6) Loosen the front and rear bolts of the motor, put thick gaskets on the front and rear legs of the motor, move the motor, try to make the two couplings close, and then tighten the front and rear bolts of the motor, at 1 o'clock. Clear the two dial indicator to zero, read the data at the 2nd and 3rd points, compare with the set allowable error value, if the accuracy requirement is not met, repeat the above steps 2-6;

(7) After step 6 is satisfied, loosen the front and rear bolts of the motor slightly, keep the dial indicator at 3 o'clock, tap the front and rear feet of the movable end, and the middle of the movable end with a copper rod, and perform horizontal alignment , Until and within the allowable error range;

(8) After step 7 is satisfied, tighten the front and back bolts of the movable end, and the alignment is complete.

4.CouplingAxial alignment

In order to correct the horizontal direction, there is no need to calculate the front and back feet of the movable end.The axial and radial kilometers are read at 1 o'clock, and the readings of the axial and radial kilometers are read at 3 o'clock. The axial direction is adjusted by tapping the movable end with a copper rod.First observe the axial reading, hit the movable ends of the front foot and the rear foot with a copper rod, and adjust the 3 point axial reading to half of the original reading.Then observe the radial kilometer reading, hit the middle of the movable end with a copper rod, and adjust the radial reading to 3 points to half of the original reading.This needs to be adjusted again and again.The adjustment result should be within the allowable error range.

Want to know aboutCouplingFor related knowledge, visit the official website:http://czwuchuan.com Coupling manufacturersAnswer for you.

Popular products

Product

Copyright © 2017-2018 Hengli Transmission All Right Reserved.