Product Description

Product Description

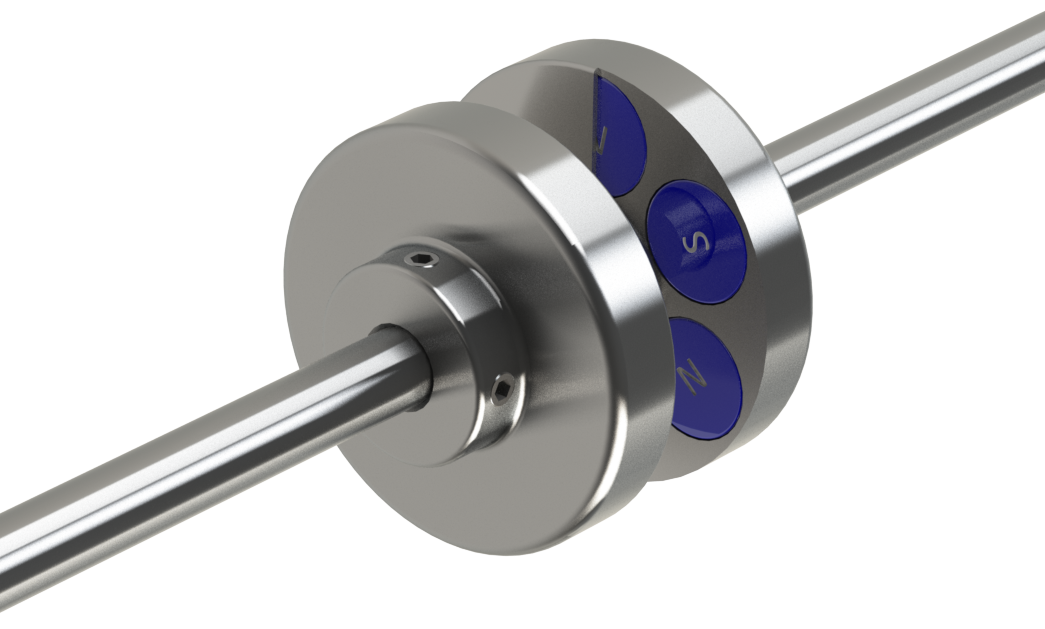

The magnetic wheel is a non-contact power transmission device that uses the principle of interaction between the attraction and the repulsion force of the magnet.

The magnetic wheel is a non-contact driven product in the production line of LCD, PDP, PCB, TFT, OLED, SOLAR CELL, etc. in a clean environment that does not allow fine impurities. It can replace mechanical gears driven by friction.

Detailed Photos

Features

| Dust-free environment | Using magnetic force, in the non-contact state, it can be used to transfer products in a vacuum where a dust-free environment is required. |

| Low gas discharge | Large machines into the vacuum machine, in order to reduce gas, according to special surface treatment, can be used in 10-5PA environment |

| Low sound | It has a subwoofer effect unimaginable in previous transmission machines such as gears and conveyor belts. Can provide a clean and tidy production environment. |

| Torque limit function | If the abnormal load is generated, the 2 magnetic gears will rotate separately to achieve the torque limit function. In addition, because of the non-contact environment, no mechanical wear, because the service life is longer than the previous transmission tools such as gears. |

| Reduce cost | Reduce operating costs without replacing parts due to wear and tear. Because even if the vacuum standby is repeated, it will not have any impact on the performance, so there is no need for complex and expensive design in the past |

Product Parameters

Using

Other Products

Packaging & Shipping

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: How to order ?

A: Normally you can order our products by using Made-in China platform or contacting representatives by Email.

After we receive your messages, we will help you to choose the right specifications and other inquiries.

Then we will send an proforma invoice to you via mail, it includes details of your order and our bank information.

After we received your payment by TT, we will ship your goods and we will send the invoice, packing list, and the express tracking number via mail.

Q: What is our term of trade ?

A: Usually we use EX WORKS. If you need other term of trade, please let us know.

Q: How to pay ?

A: We accept the payment by T/T (bank transfer) or pay through Made-in China platform.

Please inquire us about the details in advance.

Q: How are you going to deliver our goods ?

A: We can ship your goods either by air express (FedEx, DHL, UPS, TNT etc) or by sea.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Torque and Speed Limitations of Magnetic Couplings for Different Sizes and Applications

The torque and speed limitations of magnetic couplings depend on various factors, including the size of the coupling and the specific application requirements. Here’s a general overview of these limitations:

- Torque Limitations:

The torque capacity of a magnetic coupling is influenced by the strength of the magnets used, the size of the coupling, and the materials chosen for the rotor and containment shell. Larger magnetic couplings with stronger magnets and robust materials can handle higher torque requirements.

- Size and Application:

The size of the magnetic coupling plays a crucial role in determining its torque capacity. Smaller couplings are typically used in low-torque applications, such as laboratory equipment or small pumps. In contrast, larger couplings can handle higher torque demands, making them suitable for industrial-scale pumps and agitators.

- Speed Limitations:

The maximum speed at which a magnetic coupling can operate depends on several factors, including the rotational speed of the driving and driven shafts and the design of the coupling. High-speed applications, such as centrifugal pumps, require magnetic couplings designed to minimize eddy current losses and ensure stable performance at elevated speeds.

- Specialized Applications:

Some magnetic couplings are specifically designed for high-speed or high-torque applications, such as in large industrial pumps or agitators. These specialized couplings are engineered with materials and construction techniques to optimize performance under demanding conditions.

- Customization Options:

Manufacturers of magnetic couplings may offer customization options to tailor the torque and speed ratings to the specific needs of the application. This can involve selecting different magnet configurations, materials, and overall design adjustments to achieve the desired performance characteristics.

It is essential to consult with the coupling manufacturer or a qualified engineer to determine the appropriate magnetic coupling size, torque, and speed ratings for a specific application. Factors such as the fluid properties, load requirements, and environmental conditions should be taken into account to ensure the coupling’s optimal performance and reliability.

What are Some Real-World Examples of Successful Magnetic Coupling Implementations in Different Industries?

Magnetic couplings have found successful implementations in various industries, offering reliable and efficient solutions for a wide range of applications. Here are some real-world examples of their successful use:

- Chemical and Petrochemical Industry:

In chemical and petrochemical processes, magnetic couplings are employed in pumps and agitators to prevent fluid leakage and ensure a hermetically sealed system. This eliminates the risk of hazardous chemicals escaping into the environment and protects the integrity of the process.

- Pharmaceutical Industry:

In pharmaceutical manufacturing, magnetic couplings are used in mixers and reactors. The hermetically sealed design prevents contamination and allows for sterile operation, ensuring the highest level of product purity and quality.

- Food and Beverage Industry:

Magnetic couplings are used in pumps and mixers for food and beverage processing. The hermetic sealing feature ensures that there is no product contamination, meeting stringent food safety standards and maintaining the integrity of the processed food and beverages.

- Automotive Industry:

In automotive applications, magnetic couplings find use in cooling systems and turbochargers. Their high efficiency and reliability improve engine performance, and their non-contact design eliminates the need for lubrication, reducing maintenance requirements.

- Renewable Energy:

In wind turbines, magnetic couplings are used to transmit power from the turbine rotor to the generator. The maintenance-free operation and reliable power transmission make magnetic couplings a valuable component in wind turbine systems.

- Aerospace Industry:

Magnetic couplings are used in aerospace applications, such as aircraft fuel systems. Their leak-free design and tolerance to misalignment make them suitable for critical aerospace applications where safety and reliability are paramount.

- Marine Industry:

In marine applications, magnetic couplings are utilized in pumps and propulsion systems. Their ability to handle high torque and maintain efficiency at various speeds makes them suitable for different marine vessels and offshore platforms.

- Mining and Minerals:

Magnetic couplings are employed in mining equipment, such as slurry pumps. Their robust construction and tolerance to abrasive materials enhance the reliability and longevity of the mining equipment in harsh operating conditions.

These real-world examples demonstrate the versatility and effectiveness of magnetic couplings across multiple industries. Their ability to provide hermetic sealing, prevent fluid leakage, and offer reliable power transmission without mechanical wear makes them a valuable solution in critical systems where efficiency, safety, and reduced maintenance are essential considerations.

Different Types of Magnetic Couplings Used in Various Applications

Magnetic couplings come in different configurations to suit various applications and specific requirements. Some of the common types of magnetic couplings include:

- Standard Magnetic Couplings:

These are the most basic and widely used magnetic couplings. They consist of two rotors with permanent magnets and a containment shell. Standard magnetic couplings are suitable for a wide range of applications, providing non-contact power transmission, misalignment compensation, and isolation between shafts.

- High Torque Magnetic Couplings:

High torque magnetic couplings are designed to transmit higher levels of torque between the input and output shafts. They feature stronger and larger magnets to handle increased power transmission requirements. These couplings are commonly used in heavy-duty industrial applications, such as mixers, agitators, and large pumps.

- Low Torque Magnetic Couplings:

Conversely, low torque magnetic couplings are suitable for applications with lower torque demands. They have smaller and less powerful magnets, making them ideal for applications where precision and efficiency are essential, such as medical devices and laboratory equipment.

- Variable Torque Magnetic Couplings:

Variable torque magnetic couplings provide the ability to adjust the torque transmission level. These couplings can be designed with adjustable magnets or magnetic fields, allowing users to control the torque according to the specific needs of the application. They are used in systems where variable speed and torque are required, such as variable speed pumps and compressors.

- High-Speed Magnetic Couplings:

High-speed magnetic couplings are designed to handle rapid rotations without compromising on efficiency and reliability. They feature special designs and materials to reduce eddy currents and losses associated with high-speed operation. These couplings are commonly used in centrifugal pumps, turbo machinery, and high-speed motors.

- Compact Magnetic Couplings:

Compact magnetic couplings are designed to have a smaller footprint, making them suitable for applications with limited space. They are commonly used in compact pumps, microfluidic systems, and portable devices where space efficiency is crucial.

- Bi-Directional Magnetic Couplings:

Bi-directional magnetic couplings allow power transmission in both directions between the input and output shafts. They are used in applications where bidirectional rotation or periodic reversing of motion is required, such as in mixing applications and reversible pumps.

- Custom Magnetic Couplings:

Manufacturers can also create custom magnetic couplings tailored to specific applications. Custom couplings are designed to meet unique requirements, such as special torque levels, specific environmental conditions, or integration with proprietary systems.

The choice of the magnetic coupling type depends on factors such as torque requirements, speed, space constraints, environmental conditions, and the level of customization needed for the specific application.

editor by CX 2024-05-09