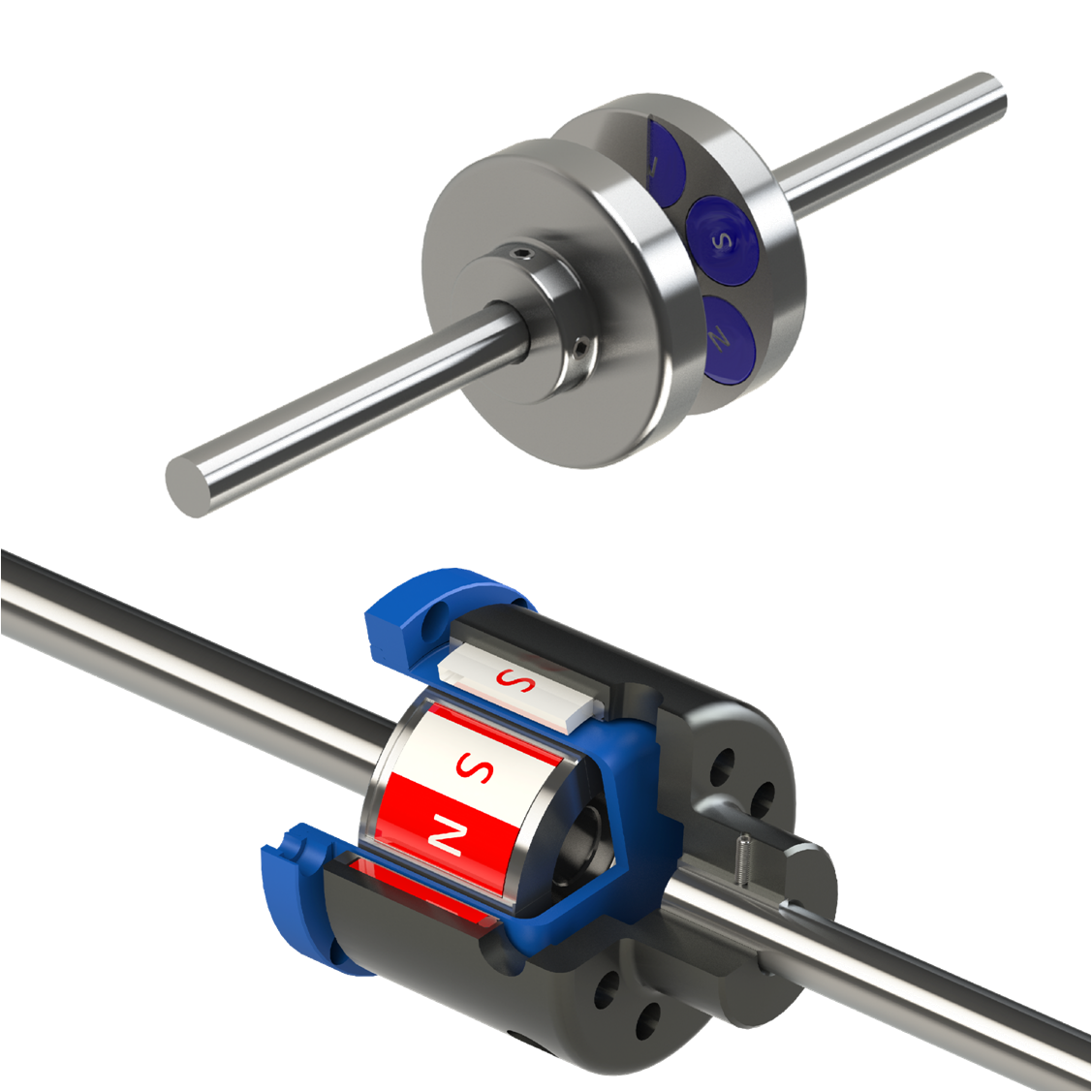

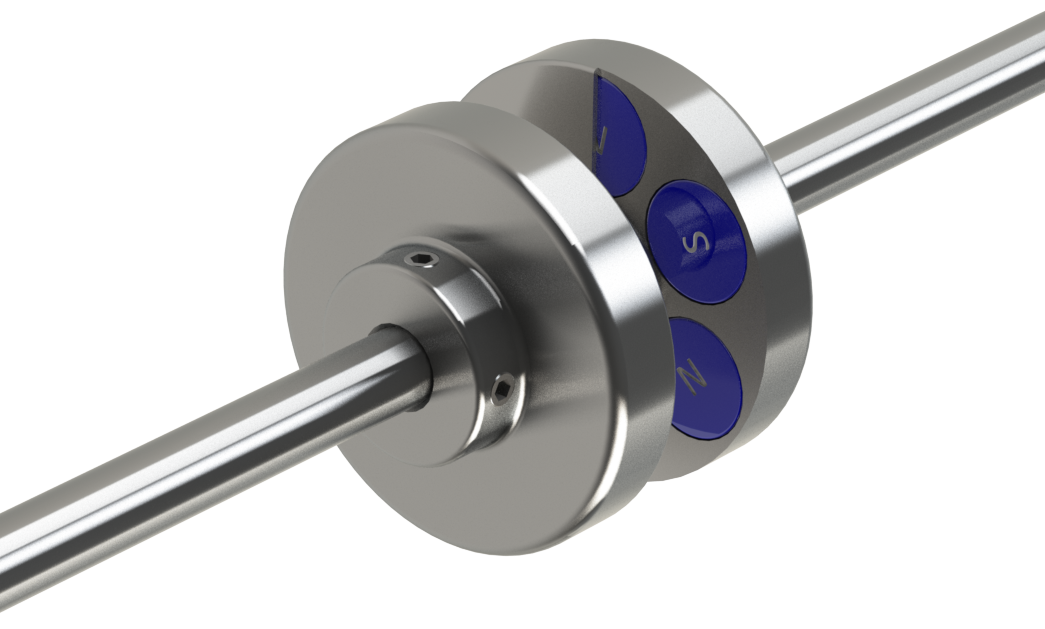

Product Description

Made in China custom Magnetic Coupling with High Quality

Introducing our custom Magnetic Coupling, proudly made in China with the highest quality standards. This coupling is designed to provide exceptional performance and reliability, making it an ideal choice for various applications.

Our Magnetic Coupling is crafted using rare earth magnets, ensuring a strong and durable connection. It offers a secure and efficient transfer of power between shafts, eliminating the need for physical contact. This feature not only reduces wear and tear but also minimizes the risk of contamination, making it suitable for sensitive environments.

Ordinary magnetic coupling, working temperature less than 80 ºC, without acid or alkali corrosion environment. Please contact customer service for customization.

| NO. | ФA | ФB | C | ФD | Фa | Фb | Фd | E | F | H | J | K | L | M | P | S | T | V | Фh | Фx | torqueN.m |

| YCL045 | 45 | 38 | 50 | 19 | 33 | 27 | 12 | 32 | 6 | 38 | 5 | 4 | 60 | 4 | 3 | 2 | 5 | 39 | 31 | 65 | 2 |

| YCL060 | 60 | 47 | 58 | 24 | 43 | 35 | 15 | 38 | 8 | 46 | 6 | 5 | 70 | 5 | 4 | 2 | 6 | 48 | 40 | 90 | 6 |

| YCL080 | 80 | 58 | 65 | 28 | 58 | 48 | 20 | 40 | 8 | 50 | 7 | 6 | 80 | 6 | 5 | 4 | 8 | 51 | 55 | 115 | 12 |

| YCL100 | 100 | 70 | 100 | 35 | 72 | 58 | 25 | 72 | 10 | 83 | 8.5 | 7 | 117 | 8 | 6 | 6 | 10 | 84 | 68 | 142 | 45 |

| YCL120 | 120 | 70 | 105 | 35 | 86 | 70 | 30 | 72 | 10 | 86 | 8.5 | 7 | 125 | 8 | 8 | 8 | 10 | 88 | 82 | 165 | 84 |

If customization is required, please contact customer service

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How Magnetic Couplings Maintain Efficiency and Reduce Power Loss During Operation

Magnetic couplings offer several features that contribute to their efficiency and help reduce power loss during operation. These characteristics ensure that the majority of the input power is effectively transferred to the driven shaft, leading to enhanced overall system performance. Here’s how magnetic couplings achieve this:

- Non-Contact Power Transmission:

Unlike mechanical couplings that rely on physical contact between components, magnetic couplings operate on the principle of magnetism. There is no friction or mechanical wear, which means there are no energy losses due to rubbing surfaces. The non-contact nature of magnetic couplings significantly reduces power loss and improves efficiency.

- Elimination of Bearings:

In traditional couplings, bearings are often used to support the shafts and minimize friction during rotation. Bearings can contribute to power loss as a portion of the input power is used to overcome bearing friction. In contrast, magnetic couplings do not require bearings for power transmission, further reducing power losses associated with bearing friction.

- Reduced Heat Generation:

Magnetic couplings generate minimal heat during operation. In mechanical couplings, friction between rotating components can lead to heat generation and energy loss. The absence of mechanical contact in magnetic couplings means that the heat generation is significantly lower, preserving energy efficiency.

- Optimized Magnetic Design:

Magnetic couplings are engineered with optimized magnetic designs to minimize eddy current losses. Eddy currents can be induced in conducting materials, such as the containment shell or rotor, leading to power dissipation. Manufacturers carefully design the coupling’s magnetic configuration to reduce eddy current losses and improve overall efficiency.

- Customization for Specific Applications:

Magnetic couplings can be customized for specific applications, allowing for efficient power transmission in diverse operating conditions. Engineers can tailor the coupling’s design, materials, and magnet configurations to match the torque and speed requirements of the application, ensuring maximum efficiency.

- Alignment Flexibility:

Magnetic couplings offer some misalignment tolerance between the driving and driven shafts. This flexibility allows for better alignment under dynamic conditions, minimizing the chances of energy losses due to misalignment-related stresses.

By combining these efficiency-enhancing features, magnetic couplings can maintain high levels of energy transfer from the driving to the driven shaft, resulting in reduced power loss and improved overall system efficiency. These advantages make magnetic couplings suitable for various applications, including pumps, agitators, and other systems where energy efficiency is critical.

Can Magnetic Couplings Be Retrofitted into Existing Systems to Enhance Performance?

Yes, magnetic couplings can be retrofitted into existing systems to enhance performance, efficiency, and reliability. Retrofitting magnetic couplings offers several benefits and is a practical solution for upgrading older systems or replacing traditional mechanical couplings with more advanced technology. Here’s how magnetic couplings can enhance the performance of existing systems:

- Improved Efficiency:

Magnetic couplings operate without direct physical contact, which reduces friction losses and improves overall system efficiency. By retrofitting a magnetic coupling, the system can experience lower energy consumption and increased power transmission efficiency.

- Elimination of Mechanical Wear:

Traditional mechanical couplings with sliding or rolling elements are prone to wear and require regular maintenance and replacement. Magnetic couplings, on the other hand, do not have any physical contact between components, eliminating the need for lubrication and reducing mechanical wear. Retrofitting with a magnetic coupling can extend the system’s lifespan and reduce maintenance costs.

- Hermetic Sealing:

Magnetic couplings offer hermetic sealing capabilities, preventing fluid leakage and contamination. By retrofitting a magnetic coupling, the system can achieve a leak-free operation, making it suitable for applications in industries such as chemical processing, pharmaceuticals, and food and beverage.

- Compatibility:

Magnetic couplings can be designed to be compatible with various systems and applications. Manufacturers offer a range of sizes and configurations to suit different retrofitting needs. Customized magnetic couplings can be engineered to match the existing system’s requirements without major modifications.

- Tolerance to Misalignment:

Magnetic couplings can accommodate a certain degree of misalignment between the driving and driven components. This misalignment tolerance can be advantageous when retrofitting into systems where precise alignment may be challenging to achieve.

- Overload Protection:

Some magnetic couplings come with built-in overload protection features. Retrofitting with such couplings can add an additional layer of safety to the system, preventing damage in case of sudden overloads or excessive torque.

When retrofitting magnetic couplings into existing systems, it is essential to work with experienced engineers or manufacturers to ensure proper sizing, alignment, and integration. Conducting a thorough evaluation of the system’s requirements and the benefits of the retrofit will help determine the best magnetic coupling solution for enhancing the performance and longevity of the existing setup.

Key Design Considerations When Using Magnetic Couplings in Pumps and Agitators

When incorporating magnetic couplings in pumps and agitators, several critical design considerations need to be taken into account to ensure effective and reliable operation. These considerations include:

- Fluid Characteristics:

Understand the properties of the fluid being handled, including viscosity, temperature, and corrosiveness. High-viscosity fluids may require larger magnets to generate sufficient torque, while corrosive fluids may necessitate materials with excellent chemical resistance.

- Torque Requirements:

Determine the required torque for the specific pump or agitator application. Magnetic couplings must be designed to transmit the necessary torque to handle the fluid flow or agitation load effectively.

- Alignment and Space Constraints:

Consider the available space and potential misalignment between the driving and driven shafts. Magnetic couplings can accommodate some misalignment, but proper alignment is essential to ensure efficient power transmission and avoid unnecessary stresses on the system.

- Speed and Efficiency:

Evaluate the speed requirements of the pump or agitator. Magnetic couplings are capable of high-speed operation, but it’s crucial to optimize the design to minimize eddy current losses and ensure maximum efficiency.

- Containment and Hermetic Sealing:

Ensure that the magnetic coupling provides adequate containment and hermetic sealing to prevent fluid leakage or contamination. This is especially critical when handling hazardous or sensitive fluids.

- Materials and Coatings:

Select appropriate materials for the magnetic coupling components based on the fluid characteristics. Stainless steel, ceramics, or specialized coatings can enhance the coupling’s durability and resistance to corrosion.

- Overload Protection:

Consider incorporating overload protection features in the magnetic coupling design. This can include slip mechanisms or torque limiters to prevent damage to the driving motor and connected equipment in case of sudden overloads or blockages.

- Environmental Conditions:

Take into account the environmental conditions in which the pump or agitator will operate. Extreme temperatures, humidity, or exposure to aggressive chemicals can influence the choice of materials and coatings for the magnetic coupling.

- Integration with System Components:

Ensure that the magnetic coupling design integrates seamlessly with other system components. Proper coupling sizing, mounting, and alignment procedures are essential for trouble-free installation and operation.

- Manufacturer Expertise:

Collaborate with manufacturers experienced in designing magnetic couplings for pumps and agitators. Work with experts who can provide customized solutions tailored to your specific application needs.

By carefully considering these design factors, you can maximize the benefits of using magnetic couplings in pumps and agitators, such as improved reliability, reduced maintenance, and enhanced system performance.

editor by CX 2024-04-04