Product Description

| Company Profile: |

Up Gold(ZheJiang )Automation Technology Co. Ltd, is a supplier of linear guide way, linear rail series,lead screw,block bearing, roller bearing ,ball bearing,pillow block bearing, rod ends bearing ,needle roller bearing,screw bearing ,slider bearings and slewing support bearings and so on.

We have exported more than 100 countries like USA, Mexico,Canada, Spain, Russia,Singapore,Thailand, India etc.We are committed to creating a one-stop shopping platform for customers to save time, improve efficiency with the best price and quality to win the trust of customers. Win-win cooperation is our company’s business philosophy.

Quality is the life of enterprise. We are committed to improving the quality of our products and services. Advanced equipment, skilled technical workers, scientific testing instrument and strict quality control, all of these factors is the key to our development and growth in the intense market competition.

Contact us now to realize the benefits of sourcing from our company. We insist to return new and old customers with best quality, fastest delivery time and most perfect after service. Your satisfaction is our goal.

| Product Feedback: |

| Product Details: |

| Product Details: |

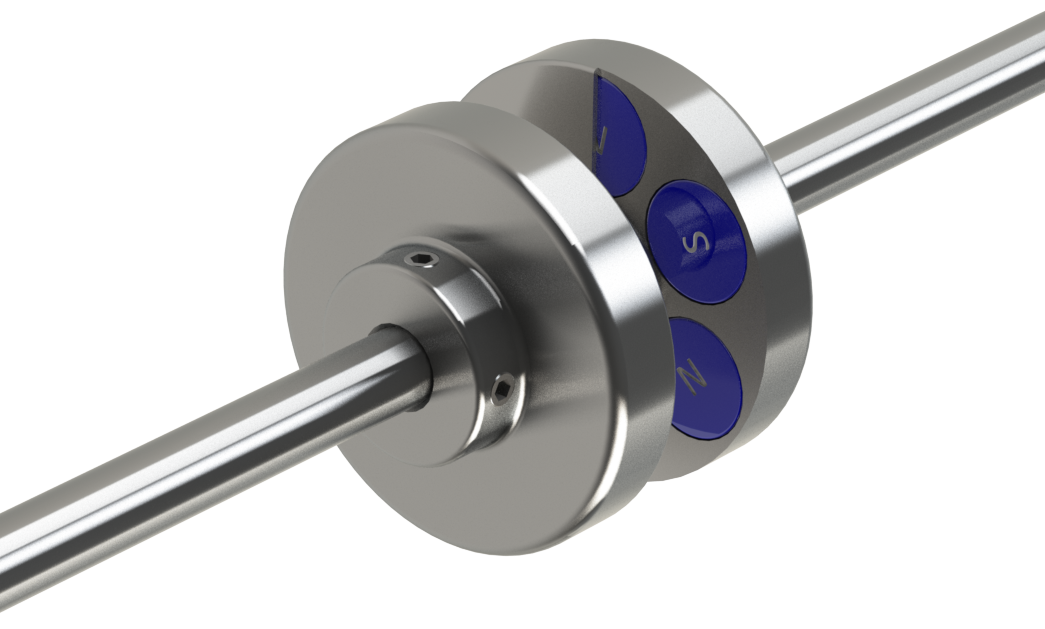

| Product Name | Coupling |

| Feature | 1. Compact Structure |

| 2.High Strength

|

|

| 3. Long Lasting | |

| 4. Anti-corrosion | |

| 5. Easy Maintenance | |

| Precision | High Precision |

| Material |

Aluminum Alloy |

| Delivery Time | 1) 1-5 Workdays for Samples or in Stock |

| 2) 10-30 Working Days for Ordering |

| Packaging and Logistics: |

| Air freight |

| Less than 45 KGS,we will send by express. |

| (Door to Door,Convenient) |

| Land transportation |

| Between 45- 150 KGS, we will send by air transport. |

| (Fastest and safest, but expensive) |

| Railway |

| More than 150 KGS,we will send by sea. |

| Shipping |

| According to the requirement of customer. |

| Product Package: |

We at Up Gold (ZheJiang ) Automation Technology Co. LTO. can offer unrivalled product and application knowledge, we can supply ballscrew products of any size or type to our valued customer.

We place huge importance on our reputation – a reputation that seems to preceed us more and more. This reputation can only grow through good service and quality products so we’re committed to expanding our range with nothing but the best products and services and the in-house knowledge to back it all up. Of course, in-house knowledge is vitally important, not just to us, but you as a customer – so we’re proud to host some of the best people in the industry.

| Our Advantages: |

*Two-year warranty, replace instead of repair.

*12 Months Warranty

*Fast Delivery

*24 hours on line service

*Professional Team

FAQ:

Q: What is the producing process?

A: Production process including raw material cutting, machine processing,grinding, accessories cleaning, assemble, cleaning, stoving, oil coating,cover pressing, testing, package.

Q: How to control the products quality?

A: Combining advanced equipment and strict management, we provide high standard and quality bearings for our customers all over the world.

Q: What is the transportation?

A: If small quantity, we suggest to send by express, such as DHL, UPS,TNT FEDEX. If large amount, by air or sea shipping.

Q: How about the shipping charge?

A: We will be free of domestic shipping charge from your freight forwarder in China.

Q: Can you provide OEM service?

A: Yes, we provide OEM service. Which means size, quantity, design,packing solution, etc will depend on your requests; and your logo will be customized on our products.

Q: Could you tell me the delivery time of your goods?

A: Generally it is 3-5 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to the quantity.

Q: What about the packaging of your products?

A: Normally we use standard commercial package, we also have our own brand packing or customized package as per customers’ requests. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can Magnetic Couplings Accommodate Misalignment Between the Driving and Driven Shafts?

Yes, magnetic couplings can accommodate a certain degree of misalignment between the driving and driven shafts. This is one of the significant advantages of using magnetic couplings over traditional mechanical couplings, which often require precise alignment to function properly.

The ability to accommodate misalignment in magnetic couplings is due to their non-contact power transmission principle. In a magnetic coupling, the driving and driven shafts are not physically connected but instead operate through a magnetic field.

When misalignment occurs between the driving and driven shafts, the magnetic fields in the magnetic coupling can adjust to compensate for the misalignment within certain limits. This means that the magnetic coupling can continue to transmit torque and power effectively, even if the shafts are not perfectly aligned.

However, it’s essential to note that while magnetic couplings offer misalignment tolerance, excessive misalignment can still lead to reduced efficiency and increased stress on the coupling components. Therefore, it is recommended to keep misalignment within the specified limits provided by the coupling manufacturer to ensure optimal performance and longevity.

By allowing for some misalignment, magnetic couplings offer greater flexibility during installation and operation. This feature is particularly valuable in applications where shaft alignment may change due to thermal expansion, vibration, or other dynamic factors.

Overall, the misalignment accommodation capability of magnetic couplings contributes to their reliability, reduces the risk of premature wear, and makes them well-suited for various industrial applications, including pumps, mixers, and other rotating equipment.

What are Some Real-World Examples of Successful Magnetic Coupling Implementations in Different Industries?

Magnetic couplings have found successful implementations in various industries, offering reliable and efficient solutions for a wide range of applications. Here are some real-world examples of their successful use:

- Chemical and Petrochemical Industry:

In chemical and petrochemical processes, magnetic couplings are employed in pumps and agitators to prevent fluid leakage and ensure a hermetically sealed system. This eliminates the risk of hazardous chemicals escaping into the environment and protects the integrity of the process.

- Pharmaceutical Industry:

In pharmaceutical manufacturing, magnetic couplings are used in mixers and reactors. The hermetically sealed design prevents contamination and allows for sterile operation, ensuring the highest level of product purity and quality.

- Food and Beverage Industry:

Magnetic couplings are used in pumps and mixers for food and beverage processing. The hermetic sealing feature ensures that there is no product contamination, meeting stringent food safety standards and maintaining the integrity of the processed food and beverages.

- Automotive Industry:

In automotive applications, magnetic couplings find use in cooling systems and turbochargers. Their high efficiency and reliability improve engine performance, and their non-contact design eliminates the need for lubrication, reducing maintenance requirements.

- Renewable Energy:

In wind turbines, magnetic couplings are used to transmit power from the turbine rotor to the generator. The maintenance-free operation and reliable power transmission make magnetic couplings a valuable component in wind turbine systems.

- Aerospace Industry:

Magnetic couplings are used in aerospace applications, such as aircraft fuel systems. Their leak-free design and tolerance to misalignment make them suitable for critical aerospace applications where safety and reliability are paramount.

- Marine Industry:

In marine applications, magnetic couplings are utilized in pumps and propulsion systems. Their ability to handle high torque and maintain efficiency at various speeds makes them suitable for different marine vessels and offshore platforms.

- Mining and Minerals:

Magnetic couplings are employed in mining equipment, such as slurry pumps. Their robust construction and tolerance to abrasive materials enhance the reliability and longevity of the mining equipment in harsh operating conditions.

These real-world examples demonstrate the versatility and effectiveness of magnetic couplings across multiple industries. Their ability to provide hermetic sealing, prevent fluid leakage, and offer reliable power transmission without mechanical wear makes them a valuable solution in critical systems where efficiency, safety, and reduced maintenance are essential considerations.

Key Design Considerations When Using Magnetic Couplings in Pumps and Agitators

When incorporating magnetic couplings in pumps and agitators, several critical design considerations need to be taken into account to ensure effective and reliable operation. These considerations include:

- Fluid Characteristics:

Understand the properties of the fluid being handled, including viscosity, temperature, and corrosiveness. High-viscosity fluids may require larger magnets to generate sufficient torque, while corrosive fluids may necessitate materials with excellent chemical resistance.

- Torque Requirements:

Determine the required torque for the specific pump or agitator application. Magnetic couplings must be designed to transmit the necessary torque to handle the fluid flow or agitation load effectively.

- Alignment and Space Constraints:

Consider the available space and potential misalignment between the driving and driven shafts. Magnetic couplings can accommodate some misalignment, but proper alignment is essential to ensure efficient power transmission and avoid unnecessary stresses on the system.

- Speed and Efficiency:

Evaluate the speed requirements of the pump or agitator. Magnetic couplings are capable of high-speed operation, but it’s crucial to optimize the design to minimize eddy current losses and ensure maximum efficiency.

- Containment and Hermetic Sealing:

Ensure that the magnetic coupling provides adequate containment and hermetic sealing to prevent fluid leakage or contamination. This is especially critical when handling hazardous or sensitive fluids.

- Materials and Coatings:

Select appropriate materials for the magnetic coupling components based on the fluid characteristics. Stainless steel, ceramics, or specialized coatings can enhance the coupling’s durability and resistance to corrosion.

- Overload Protection:

Consider incorporating overload protection features in the magnetic coupling design. This can include slip mechanisms or torque limiters to prevent damage to the driving motor and connected equipment in case of sudden overloads or blockages.

- Environmental Conditions:

Take into account the environmental conditions in which the pump or agitator will operate. Extreme temperatures, humidity, or exposure to aggressive chemicals can influence the choice of materials and coatings for the magnetic coupling.

- Integration with System Components:

Ensure that the magnetic coupling design integrates seamlessly with other system components. Proper coupling sizing, mounting, and alignment procedures are essential for trouble-free installation and operation.

- Manufacturer Expertise:

Collaborate with manufacturers experienced in designing magnetic couplings for pumps and agitators. Work with experts who can provide customized solutions tailored to your specific application needs.

By carefully considering these design factors, you can maximize the benefits of using magnetic couplings in pumps and agitators, such as improved reliability, reduced maintenance, and enhanced system performance.

editor by CX 2024-04-03