Product Description

Quick coupling hoodies sweatshirt statue underwear magnetic bracelets tubing watch luxury sex accessories tracksuite galvanized steel stainless steel

Application of Quick coupling

Quick couplings are a type of connector that allows for the rapid and easy connection and disconnection of fluid lines. They are typically used in pneumatic and hydraulic systems, and they can be found in a variety of industries, including manufacturing, construction, and agriculture.

Quick couplings are available in a variety of sizes and styles, and they can be made from a variety of materials, including metal, plastic, and rubber. The type of quick coupling that is best suited for a particular application will depend on the size and type of fluid lines that are being connected, as well as the environmental conditions in which the coupling will be used.

Quick couplings offer a number of advantages over traditional connectors, including:

- They can be connected and disconnected quickly and easily, without the need for tools.

- They can be used with a variety of different fluid lines.

- They are relatively leak-proof.

- They are durable and can withstand a variety of environmental conditions.

Quick couplings are a versatile and reliable type of connector that can be used in a variety of applications. They are a good choice for applications where rapid and easy connection and disconnection of fluid lines is required.

Here are some of the applications of quick couplings:

- Pneumatic systems: Quick couplings are commonly used in pneumatic systems to connect and disconnect air lines.

- Hydraulic systems: Quick couplings are commonly used in hydraulic systems to connect and disconnect fluid lines.

- Construction: Quick couplings are commonly used in construction to connect and disconnect water lines and other fluid lines.

- Agriculture: Quick couplings are commonly used in agriculture to connect and disconnect irrigation lines and other fluid lines.

- Other: Quick couplings are also used in a variety of other applications, such as in the automotive industry and the medical field.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

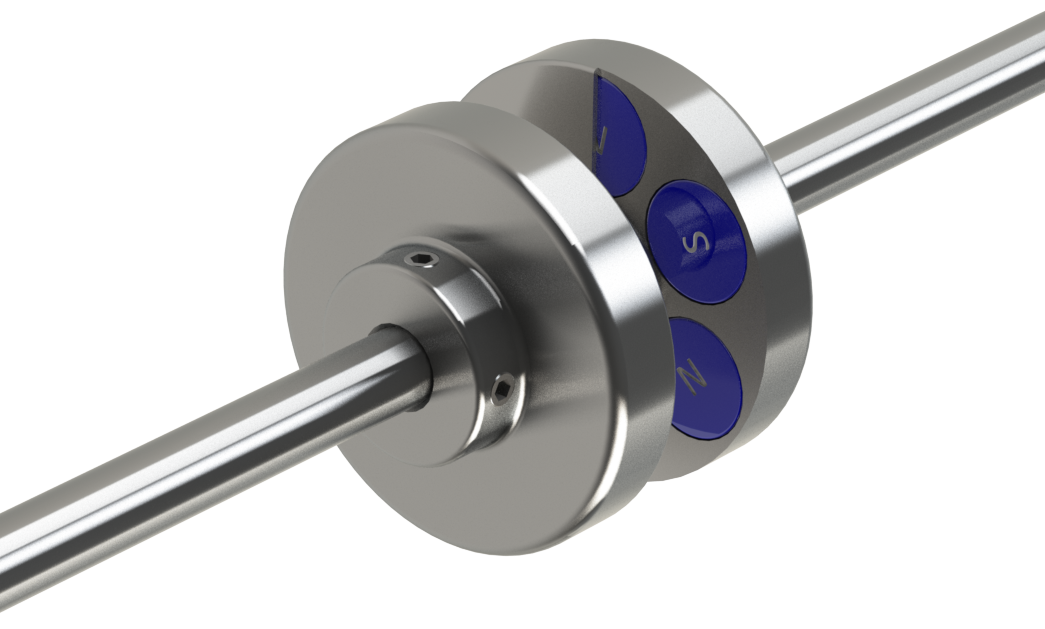

Can Magnetic Couplings Accommodate Misalignment Between the Driving and Driven Shafts?

Yes, magnetic couplings can accommodate a certain degree of misalignment between the driving and driven shafts. This is one of the significant advantages of using magnetic couplings over traditional mechanical couplings, which often require precise alignment to function properly.

The ability to accommodate misalignment in magnetic couplings is due to their non-contact power transmission principle. In a magnetic coupling, the driving and driven shafts are not physically connected but instead operate through a magnetic field.

When misalignment occurs between the driving and driven shafts, the magnetic fields in the magnetic coupling can adjust to compensate for the misalignment within certain limits. This means that the magnetic coupling can continue to transmit torque and power effectively, even if the shafts are not perfectly aligned.

However, it’s essential to note that while magnetic couplings offer misalignment tolerance, excessive misalignment can still lead to reduced efficiency and increased stress on the coupling components. Therefore, it is recommended to keep misalignment within the specified limits provided by the coupling manufacturer to ensure optimal performance and longevity.

By allowing for some misalignment, magnetic couplings offer greater flexibility during installation and operation. This feature is particularly valuable in applications where shaft alignment may change due to thermal expansion, vibration, or other dynamic factors.

Overall, the misalignment accommodation capability of magnetic couplings contributes to their reliability, reduces the risk of premature wear, and makes them well-suited for various industrial applications, including pumps, mixers, and other rotating equipment.

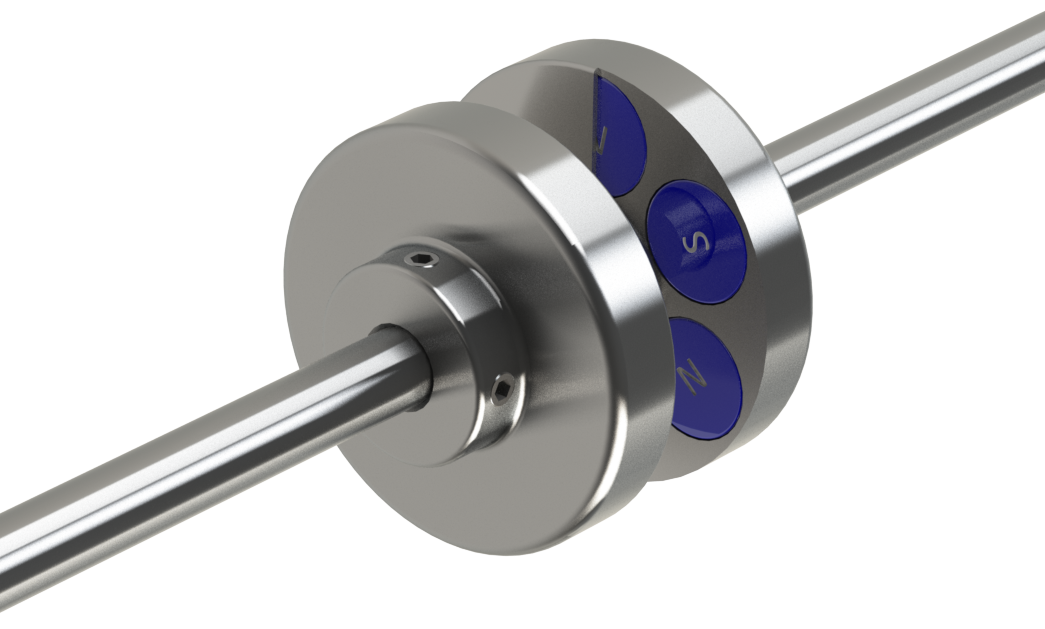

What materials, such as neodymium or samarium cobalt, are commonly used in manufacturing magnetic couplings?

Magnetic couplings utilize magnets made from various materials to transfer torque and power without physical contact. Some of the common materials used in manufacturing magnetic couplings include:

- Neodymium Iron Boron (NdFeB):

Neodymium magnets are the most widely used type of permanent magnets in magnetic couplings. They offer excellent magnetic properties, high energy density, and strong magnetic fields, making them highly efficient for power transmission. NdFeB magnets are known for their strong magnetic pull and are suitable for various applications with demanding torque requirements.

- Samarium Cobalt (SmCo):

Samarium cobalt magnets are another popular choice for magnetic couplings. They exhibit high magnetic stability, even at high temperatures, and have excellent corrosion resistance. SmCo magnets are often used in applications where extreme operating conditions, such as elevated temperatures or aggressive environments, are present.

- Alnico:

Alnico magnets are an older type of permanent magnet, known for their high magnetic strength and thermal stability. While not as powerful as neodymium magnets, alnico magnets are still used in certain magnetic coupling applications, especially in situations where the operating temperature is a critical factor.

- Ceramic Magnets (Ferrite):

Ceramic magnets, also known as ferrite magnets, are cost-effective and widely used in various magnetic coupling designs. They have moderate magnetic strength and are suitable for applications with less demanding torque requirements.

The selection of magnet material for a magnetic coupling depends on the specific application requirements, such as the desired torque transmission, operating temperature, and environmental factors. Manufacturers may also incorporate different magnet configurations and arrangements to optimize the coupling’s performance for a particular application.

Different Types of Magnetic Couplings Used in Various Applications

Magnetic couplings come in different configurations to suit various applications and specific requirements. Some of the common types of magnetic couplings include:

- Standard Magnetic Couplings:

These are the most basic and widely used magnetic couplings. They consist of two rotors with permanent magnets and a containment shell. Standard magnetic couplings are suitable for a wide range of applications, providing non-contact power transmission, misalignment compensation, and isolation between shafts.

- High Torque Magnetic Couplings:

High torque magnetic couplings are designed to transmit higher levels of torque between the input and output shafts. They feature stronger and larger magnets to handle increased power transmission requirements. These couplings are commonly used in heavy-duty industrial applications, such as mixers, agitators, and large pumps.

- Low Torque Magnetic Couplings:

Conversely, low torque magnetic couplings are suitable for applications with lower torque demands. They have smaller and less powerful magnets, making them ideal for applications where precision and efficiency are essential, such as medical devices and laboratory equipment.

- Variable Torque Magnetic Couplings:

Variable torque magnetic couplings provide the ability to adjust the torque transmission level. These couplings can be designed with adjustable magnets or magnetic fields, allowing users to control the torque according to the specific needs of the application. They are used in systems where variable speed and torque are required, such as variable speed pumps and compressors.

- High-Speed Magnetic Couplings:

High-speed magnetic couplings are designed to handle rapid rotations without compromising on efficiency and reliability. They feature special designs and materials to reduce eddy currents and losses associated with high-speed operation. These couplings are commonly used in centrifugal pumps, turbo machinery, and high-speed motors.

- Compact Magnetic Couplings:

Compact magnetic couplings are designed to have a smaller footprint, making them suitable for applications with limited space. They are commonly used in compact pumps, microfluidic systems, and portable devices where space efficiency is crucial.

- Bi-Directional Magnetic Couplings:

Bi-directional magnetic couplings allow power transmission in both directions between the input and output shafts. They are used in applications where bidirectional rotation or periodic reversing of motion is required, such as in mixing applications and reversible pumps.

- Custom Magnetic Couplings:

Manufacturers can also create custom magnetic couplings tailored to specific applications. Custom couplings are designed to meet unique requirements, such as special torque levels, specific environmental conditions, or integration with proprietary systems.

The choice of the magnetic coupling type depends on factors such as torque requirements, speed, space constraints, environmental conditions, and the level of customization needed for the specific application.

editor by CX 2024-04-15