Product Description

Hot sale: low noise,no leakage, no additional cost for motor coupling magnetic coupling pump motor shaft coupling

Please send us following information.

1. Motor output power(KW)

2. Motor speed(RPM)

3.Torque of the mangetic coupling

4. Working pressure of the housing(isolation sleeve)

5.Working temperature of magnetic coupling

6. Technical drawing of the output part connector (usually motor)

7. Technical drawing of the input part connector (usually pump)

Introduction of motor coupling magnetic coupling pump motor shaft coupling

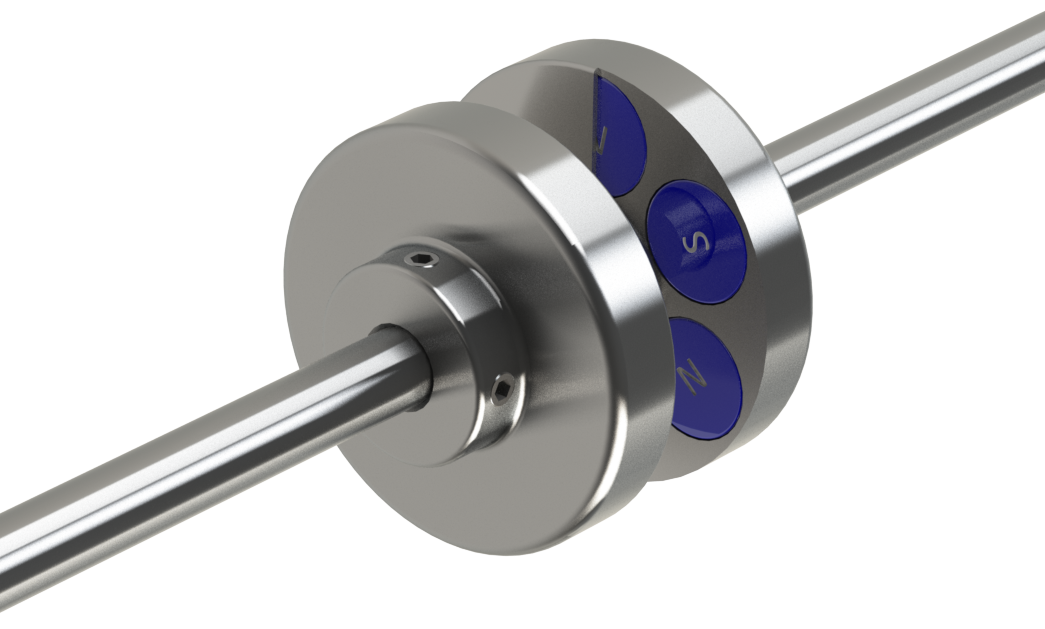

Magnetic shaft coupling is a new kind of coupling, which connects motor and machine by permanent magnetic force.

They are consisted of external rotor, internal rotor and isolating covers.

They work in the sealed magnetic drive pumps, which transporting volatile, flammable, explosive and toxic solutions with no leakage.

These magnetic shaft couplings can be used to connect gear pumps , screw pumps, centrifugal pumps, etc. with all types of electric motor or gear box.

Magnetic shaft coupling are widely used in various industries and fields, such as chemical, papermaking, foodstuff, pharmacy, and so on.

Advantages of motor coupling magnetic coupling pump motor shaft coupling

» Elimination of fluid leakage from the pump shaft.

» Vibrations are not transmitted to the pump.

» No maintenance required for magnetic couplings.

» Using magnetic couplings allows use of standard pumps without expensive mechanical seals.

» No additional cost for purchasing mechanical seal spare parts and maintenance.

Technical drawing of motor coupling magnetic coupling pump motor shaft coupling

Specification of motor coupling magnetic coupling pump motor shaft coupling

| Item | Internal Rotor(mm) | External Rotor(mm) | Isolating Covering(mm) | |||||||||||||||||

| A | B | C | D | E | F | G | Shaft Pin | H | I | J | L | N | M | P | Q | R | S | T | U | |

| GME03-3LM00 | Φ35 | – | Φ10 | 26 | – | 18 | – | M6X12 | Φ42 | Φ60 | Φ50 | 46 | 6-M4 | Φ40 | Φ50 | 4-Φ5.4 | Φ38 | Φ60 | 6 | 6 |

| GME03-5MM00 | Φ42 | – | Φ12 | 27 | 4 | 18 | 13.8 | M6X16 | Φ49 | Φ72 | Φ60 | 46 | 4-Φ6.7 | Φ52 | Φ60 | 4-Φ6.7 | Φ44 | Φ74 | 8 | 8 |

| GME03-16LM00 | Φ56 | – | Φ12 | 45 | 4 | 25 | 13.8 | M6X16 | Φ63 | Φ89 | Φ80 | 75 | 6-M5 | Φ70 | Φ75 | 4-Φ6.7 | Φ58 | Φ89 | 8 | 8 |

| GME03-16LM01 | Φ56 | – | Φ12 | 45 | 4 | 25 | 13.8 | M6X16 | Φ63 | Φ89 | Φ80 | 75 | 4-M5 | Φ70 | Φ75 | 4-Φ6.7 | Φ58 | Φ89 | 6 | 10 |

| GME03-16MM00 | Φ56 | – | Φ12 | 45 | 4 | 25 | 13.8 | M6X16 | Φ63 | Φ89 | Φ80 | 75 | 6-M5 | Φ70 | Φ75 | 4-Φ6.7 | Φ58 | Φ89 | 8 | 8 |

| GME03-22LM00 | Φ88 | – | Φ20 | 29 | 6 | 25 | 22.8 | M8X20 | Φ97 | Φ122 | Φ110 | 70 | 8-M6 | Φ98 | Φ108 | 6-Φ6.7 | Φ91 | Φ122 | 8 | 8 |

| GME03-30LM00 | Φ88 | – | Φ20 | 48 | 6 | 30 | 22.8 | M8X20 | Φ97 | Φ122 | Φ110 | 81 | 8-M6 | Φ98 | Φ108 | 6-Φ6.7 | Φ91 | Φ122 | 8 | 8 |

| GME03-40LM00 | Φ101 | – | Φ25 | 49 | 8 | 28 | 28.3 | M10X20 | Φ109 | Φ140 | Φ124 | 83 | 8-M8 | Φ110 | Φ126 | 8-Φ6.7 | Φ103 | Φ140 | 12 | 6 |

| GME03-50LM00 | Φ107 | – | Φ20 | 70 | 6 | 30 | 22.8 | M6X16 | Φ113.4 | Φ145 | Φ135 | 80 | 4-M6 | Φ126 | Φ133 | 12-Φ8.7 | Φ109 | Φ153 | 12 | 15 |

| GME03-65LM00 | Φ101 | – | Φ25 | 77 | 8 | 45 | 28.3 | M10X20 | Φ109 | Φ140 | Φ124 | 111 | 8-M8 | Φ110 | Φ126 | 8-Φ6.7 | Φ103 | Φ140 | 12 | 6 |

| GME03-80LM00 | Φ106 | – | Φ32 | 65 | 10 | 21 | 36.5 | M6X25 | Φ115 | Φ145 | Φ135 | 82 | 4-M6 | Φ127 | Φ135 | 6-Φ8.7 | Φ110 | Φ153 | 13 | 18 |

| GME03-80LM00 | Φ141 | Φ92 | Φ40 | 65 | 12 | 45 | 43.3 | M12X25 | Φ152 | Φ180 | Φ168 | 100 | 8-M8 | Φ154 | Φ164 | 8-Φ6.7 | Φ145 | Φ180 | 12 | 8 |

| GME03-100LM00 | Φ131 | Φ82 | Φ32 | 80 | 10 | 24.5 | 35.3 | M8X35 | Φ139 | Φ170 | Φ160 | 100 | 4-M6 | Φ152 | Φ158 | 8-Φ8.7 | Φ133 | Φ178 | 14 | 21 |

| GME03-110LH00 | Φ141 | Φ92 | Φ40 | 85 | 10 | 50 | 43.3 | M12X25 | Φ152 | Φ184 | Φ168 | 115 | 12-M8 | Φ156 | Φ164 | 12-Φ6.7 | Φ145 | Φ180 | 12 | 3 |

| GME03-110LM00 | Φ141 | Φ92 | Φ35 | 80 | 10 | 55 | 38.3 | M12X25 | Φ152 | Φ180 | Φ168 | 115 | 12-M8 | Φ154 | Φ164 | 12-Φ6.7 | Φ145 | Φ180 | 12 | 3 |

| GME03-140LM00 | Φ141 | Φ92 | Φ40 | 110 | 12 | 80 | 43.3 | M12X25 | Φ152 | Φ190 | Φ170 | 145 | 12-M10 | Φ154 | Φ164 | 12-Φ6.7 | Φ145 | Φ180 | 12 | 3 |

| GME03-180LM00 | Φ141 | Φ92 | Φ40 | 140 | 12 | 95 | 43.3 | M12X25 | Φ152 | Φ190 | Φ170 | 175 | 12-M10 | Φ154 | Φ164 | 12-Φ6.7 | Φ145 | Φ180 | 12 | 3 |

| GME03-220LM00 | Φ141 | Φ92 | Φ48 | 160 | 14 | 110 | 51.8 | M12X25 | Φ152 | Φ190 | Φ170 | 195 | 12-M10 | Φ154 | Φ164 | 12-Φ6.7 | Φ145 | Φ180 | 12 | 3 |

| GME03-300LM00 | Φ162 | – | Φ65 | 100 | 18 | 60 | 69.4 | Φ170 | Φ198 | Φ188 | 123 | 12-M6 | Φ180 | Φ192 | 12-Φ11 | Φ163.5 | Φ218 | 16 | 10 | |

| GME03-400LH00 | Φ195 | – | Φ70 | 127 | 20 | 107 | 79.9 | M12X25 | Φ203 | Φ234 | Φ222 | 152 | 6-M6 | Φ212 | Φ164 | 12-Φ11 | Φ198 | Φ278 | 16 | 22 |

Application of motor coupling magnetic coupling pump motor shaft coupling

The ability to hermetically separate 2 areas whilst continuing to transmit mechanical power from one to the other makes these couplings ideal for applications where prevention of cross contamination is essential. For instance: hydraulic sectors, dosing systems, compressors, sterilizers, industrial ovens, biotechnology, subsea equipment, pharmaceutical industry, chemical industry, food industry, generators and mixers.

Operation principles of motor coupling magnetic coupling pump motor shaft coupling

The magnetic coupling works by using the power generated by permanent magnets. No external power supply is needed. These are permanent magnets not electro magnets.

Packing Method of motor coupling magnetic coupling pump motor shaft coupling

Double strength corrugated Carton and Wood case Sea Packing.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can Magnetic Couplings Be Used in Applications Involving Corrosive or Aggressive Fluids?

Yes, magnetic couplings can be used in applications involving corrosive or aggressive fluids, provided that the coupling is constructed using materials that are compatible with the specific fluid being handled. The ability to use magnetic couplings with corrosive or aggressive fluids depends on the material selection and design of the coupling.

When handling corrosive or aggressive fluids, it’s essential to consider the following factors:

- Material Compatibility:

Select materials for the magnetic coupling that are resistant to the corrosive properties of the fluid. For example, stainless steel, Hastelloy, or certain grades of ceramics are commonly used for components that come into contact with corrosive fluids.

- Hermetic Sealing:

Ensure that the magnetic coupling provides a hermetic seal to prevent fluid leakage. The containment shell and other sealing components must be able to withstand the chemical properties of the aggressive fluid.

- Coatings and Lining:

In some cases, coatings or lining materials can be applied to the coupling’s surfaces that are exposed to the fluid. These coatings can offer additional protection against corrosion and ensure compatibility with aggressive fluids.

- Fluid Temperature and Pressure:

Consider the temperature and pressure of the aggressive fluid, as it may influence the material selection and design of the magnetic coupling. High temperatures or pressures can impact the coupling’s performance and material integrity.

- Fluid Properties:

Understand the specific chemical properties of the aggressive fluid, such as acidity, alkalinity, or reactivity. This information is crucial for selecting appropriate materials and ensuring the coupling can handle the fluid’s properties.

- Manufacturer’s Recommendations:

Consult the magnetic coupling manufacturer for their recommendations on material selection and design considerations for applications involving corrosive or aggressive fluids. They can provide guidance based on their expertise and product specifications.

By carefully considering material compatibility and design factors, magnetic couplings can be successfully used in a wide range of applications involving corrosive or aggressive fluids. These couplings offer advantages such as leak-free operation, reduced maintenance, and the absence of wear-prone components, making them suitable for various industries, including chemical processing, petrochemicals, and pharmaceuticals.

What materials, such as neodymium or samarium cobalt, are commonly used in manufacturing magnetic couplings?

Magnetic couplings utilize magnets made from various materials to transfer torque and power without physical contact. Some of the common materials used in manufacturing magnetic couplings include:

- Neodymium Iron Boron (NdFeB):

Neodymium magnets are the most widely used type of permanent magnets in magnetic couplings. They offer excellent magnetic properties, high energy density, and strong magnetic fields, making them highly efficient for power transmission. NdFeB magnets are known for their strong magnetic pull and are suitable for various applications with demanding torque requirements.

- Samarium Cobalt (SmCo):

Samarium cobalt magnets are another popular choice for magnetic couplings. They exhibit high magnetic stability, even at high temperatures, and have excellent corrosion resistance. SmCo magnets are often used in applications where extreme operating conditions, such as elevated temperatures or aggressive environments, are present.

- Alnico:

Alnico magnets are an older type of permanent magnet, known for their high magnetic strength and thermal stability. While not as powerful as neodymium magnets, alnico magnets are still used in certain magnetic coupling applications, especially in situations where the operating temperature is a critical factor.

- Ceramic Magnets (Ferrite):

Ceramic magnets, also known as ferrite magnets, are cost-effective and widely used in various magnetic coupling designs. They have moderate magnetic strength and are suitable for applications with less demanding torque requirements.

The selection of magnet material for a magnetic coupling depends on the specific application requirements, such as the desired torque transmission, operating temperature, and environmental factors. Manufacturers may also incorporate different magnet configurations and arrangements to optimize the coupling’s performance for a particular application.

Different Types of Magnetic Couplings Used in Various Applications

Magnetic couplings come in different configurations to suit various applications and specific requirements. Some of the common types of magnetic couplings include:

- Standard Magnetic Couplings:

These are the most basic and widely used magnetic couplings. They consist of two rotors with permanent magnets and a containment shell. Standard magnetic couplings are suitable for a wide range of applications, providing non-contact power transmission, misalignment compensation, and isolation between shafts.

- High Torque Magnetic Couplings:

High torque magnetic couplings are designed to transmit higher levels of torque between the input and output shafts. They feature stronger and larger magnets to handle increased power transmission requirements. These couplings are commonly used in heavy-duty industrial applications, such as mixers, agitators, and large pumps.

- Low Torque Magnetic Couplings:

Conversely, low torque magnetic couplings are suitable for applications with lower torque demands. They have smaller and less powerful magnets, making them ideal for applications where precision and efficiency are essential, such as medical devices and laboratory equipment.

- Variable Torque Magnetic Couplings:

Variable torque magnetic couplings provide the ability to adjust the torque transmission level. These couplings can be designed with adjustable magnets or magnetic fields, allowing users to control the torque according to the specific needs of the application. They are used in systems where variable speed and torque are required, such as variable speed pumps and compressors.

- High-Speed Magnetic Couplings:

High-speed magnetic couplings are designed to handle rapid rotations without compromising on efficiency and reliability. They feature special designs and materials to reduce eddy currents and losses associated with high-speed operation. These couplings are commonly used in centrifugal pumps, turbo machinery, and high-speed motors.

- Compact Magnetic Couplings:

Compact magnetic couplings are designed to have a smaller footprint, making them suitable for applications with limited space. They are commonly used in compact pumps, microfluidic systems, and portable devices where space efficiency is crucial.

- Bi-Directional Magnetic Couplings:

Bi-directional magnetic couplings allow power transmission in both directions between the input and output shafts. They are used in applications where bidirectional rotation or periodic reversing of motion is required, such as in mixing applications and reversible pumps.

- Custom Magnetic Couplings:

Manufacturers can also create custom magnetic couplings tailored to specific applications. Custom couplings are designed to meet unique requirements, such as special torque levels, specific environmental conditions, or integration with proprietary systems.

The choice of the magnetic coupling type depends on factors such as torque requirements, speed, space constraints, environmental conditions, and the level of customization needed for the specific application.

editor by CX 2024-04-29