Product Description

You can kindly find the specification details below:

HangZhou Mastery Machinery Technology Co., LTD helps manufacturers and brands fulfill their machinery parts by precision manufacturing. High precision machinery products like the shaft, worm screw, bushing, joints, couplings……Our products are used widely in electronic motors, the main shaft of the engine, the transmission shaft in the gearbox, couplers, printers, pumps, drones, and so on. They cater to different industries, including automotive, industrial, power tools, garden tools, healthcare, smart home, etc.

Mastery caters to the industrial industry by offering high-level Cardan shafts, pump shafts, and a bushing that come in different sizes ranging from diameter 3mm-50mm. Our products are specifically formulated for transmissions, robots, gearboxes, industrial fans, and drones, etc.

Mastery factory currently has more than 100 main production equipment such as CNC lathe, CNC machining center, CAM Automatic Lathe, grinding machine, hobbing machine, etc. The production capacity can be up to 5-micron mechanical tolerance accuracy, automatic wiring machine processing range covering 3mm-50mm diameter bar.

Key Specifications:

| Name | Shaft/Motor Shaft/Drive Shaft/Gear Shaft/Pump Shaft/Worm Screw/Worm Gear/Bushing/Ring/Joint/Pin |

| Material | 40Cr/35C/GB45/70Cr/40CrMo |

| Process | Machining/Lathing/Milling/Drilling/Grinding/Polishing |

| Size | 2-400mm(Customized) |

| Diameter | φ5.2mm(Customized) |

| Diameter Tolerance | ±0.02mm |

| Roundness | 0.05mm |

| Roughness | Ra0.4 |

| Straightness | N.A |

| Hardness | N.A |

| Length | 4.3mm(Customized) |

| Heat Treatment | Customized |

| Surface treatment | Coating/Ni plating/Zn plating/QPQ/Carbonization/Quenching/Black Treatment/Steaming Treatment/Nitrocarburizing/Carbonitriding |

Quality Management:

- Raw Material Quality Control: Chemical Composition Analysis, Mechanical Performance Test, ROHS, and Mechanical Dimension Check

- Production Process Quality Control: Full-size inspection for the 1st part, Critical size process inspection, SPC process monitoring

- Lab ability: CMM, OGP, XRF, Roughness meter, Profiler, Automatic optical inspector

- Quality system: ISO9001, IATF 16949, ISO14001

- Eco-Friendly: ROHS, Reach.

Packaging and Shipping:

Throughout the entire process of our supply chain management, consistent on-time delivery is vital and very important for the success of our business.

Mastery utilizes several different shipping methods that are detailed below:

For Samples/Small Q’ty: By Express Services or Air Fright.

For Formal Order: By Sea or by air according to your requirement.

Mastery Services:

- One-Stop solution from idea to product/ODM&OEM acceptable

- Individual research and sourcing/purchasing tasks

- Individual supplier management/development, on-site quality check projects

- Muti-varieties/small batch/customization/trial orders are acceptable

- Flexibility on quantity/Quick samples

- Forecast and raw material preparation in advance are negotiable

- Quick quotes and quick responses

General Parameters:

If you are looking for a reliable machinery product partner, you can rely on Mastery. Work with us and let us help you grow your business using our customizable and affordable products. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Are there any Safety Considerations or Guidelines for Using Magnetic Couplings in Hazardous Environments?

Yes, when using magnetic couplings in hazardous environments, there are several safety considerations and guidelines that should be followed to ensure the safety of personnel and equipment. Hazardous environments may involve flammable, explosive, or corrosive substances, and it’s crucial to address potential risks. Here are the safety considerations and guidelines:

- Material Selection:

Choose magnetic couplings constructed from materials that are compatible with the hazardous substances present in the environment. For example, some chemicals may be corrosive, so the coupling’s materials must resist corrosion to maintain integrity.

- Sealing:

Ensure that the magnetic coupling provides a hermetic seal to prevent fluid leakage and the release of hazardous substances into the environment. The containment shell should be designed to withstand the pressures and temperatures of the specific application.

- Explosion-Proof:

In environments where flammable or explosive substances are present, consider using explosion-proof magnetic couplings. These couplings are designed to prevent the ignition of flammable gases or vapors in the event of a fault.

- Compliance with Regulations:

Ensure that the magnetic coupling meets all relevant safety and industry standards for hazardous environments. Compliance with regulations, such as ATEX or IECEx, is essential to ensure the coupling’s suitability for use in specific hazardous locations.

- Environmental Conditions:

Evaluate the environmental conditions of the hazardous area, including temperature, pressure, and chemical exposure. The magnetic coupling should be rated and designed to withstand the specific conditions of the environment.

- Grounding:

Properly ground the magnetic coupling and the associated equipment to dissipate any static charges and prevent sparks that could ignite flammable substances.

- Installation and Maintenance:

Follow the manufacturer’s recommended installation and maintenance procedures to ensure the magnetic coupling functions correctly in the hazardous environment. Regular inspections and maintenance are essential to identify and address any potential issues.

- Training and Awareness:

Provide training to personnel working in the hazardous area about the risks associated with magnetic couplings and the proper procedures to follow in case of any abnormalities or emergencies.

It is crucial to consult with experts or engineers experienced in hazardous environments to ensure that the magnetic coupling is appropriately selected and installed for the specific application. Following these safety considerations and guidelines will help mitigate risks and ensure safe operation in hazardous environments.

Can Magnetic Couplings Be Retrofitted into Existing Systems to Enhance Performance?

Yes, magnetic couplings can be retrofitted into existing systems to enhance performance, efficiency, and reliability. Retrofitting magnetic couplings offers several benefits and is a practical solution for upgrading older systems or replacing traditional mechanical couplings with more advanced technology. Here’s how magnetic couplings can enhance the performance of existing systems:

- Improved Efficiency:

Magnetic couplings operate without direct physical contact, which reduces friction losses and improves overall system efficiency. By retrofitting a magnetic coupling, the system can experience lower energy consumption and increased power transmission efficiency.

- Elimination of Mechanical Wear:

Traditional mechanical couplings with sliding or rolling elements are prone to wear and require regular maintenance and replacement. Magnetic couplings, on the other hand, do not have any physical contact between components, eliminating the need for lubrication and reducing mechanical wear. Retrofitting with a magnetic coupling can extend the system’s lifespan and reduce maintenance costs.

- Hermetic Sealing:

Magnetic couplings offer hermetic sealing capabilities, preventing fluid leakage and contamination. By retrofitting a magnetic coupling, the system can achieve a leak-free operation, making it suitable for applications in industries such as chemical processing, pharmaceuticals, and food and beverage.

- Compatibility:

Magnetic couplings can be designed to be compatible with various systems and applications. Manufacturers offer a range of sizes and configurations to suit different retrofitting needs. Customized magnetic couplings can be engineered to match the existing system’s requirements without major modifications.

- Tolerance to Misalignment:

Magnetic couplings can accommodate a certain degree of misalignment between the driving and driven components. This misalignment tolerance can be advantageous when retrofitting into systems where precise alignment may be challenging to achieve.

- Overload Protection:

Some magnetic couplings come with built-in overload protection features. Retrofitting with such couplings can add an additional layer of safety to the system, preventing damage in case of sudden overloads or excessive torque.

When retrofitting magnetic couplings into existing systems, it is essential to work with experienced engineers or manufacturers to ensure proper sizing, alignment, and integration. Conducting a thorough evaluation of the system’s requirements and the benefits of the retrofit will help determine the best magnetic coupling solution for enhancing the performance and longevity of the existing setup.

What is a Magnetic Coupling and How Does It Function in Mechanical Power Transmission?

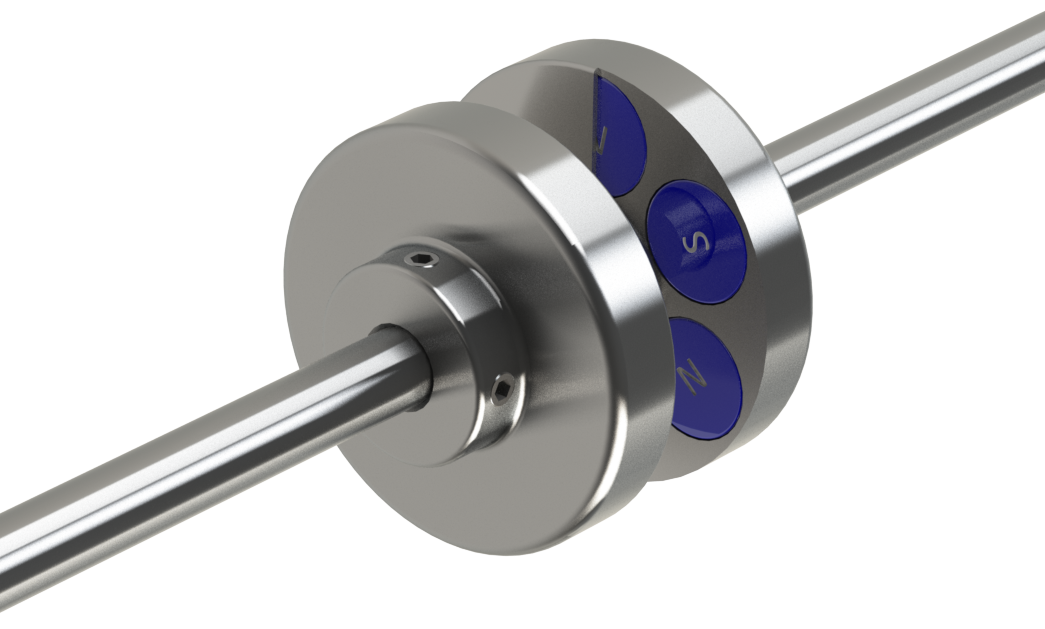

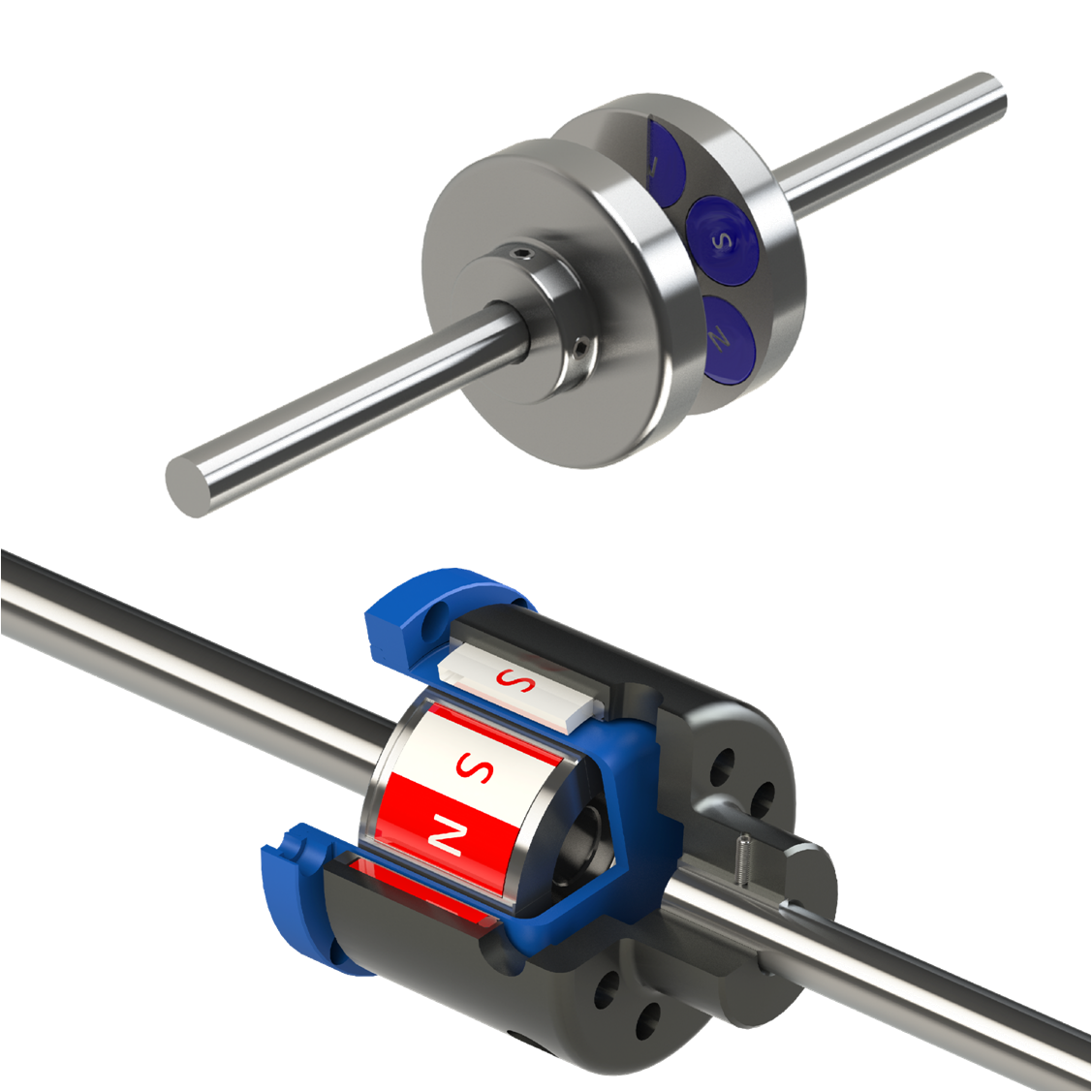

A magnetic coupling is a type of coupling used in mechanical power transmission systems to transfer torque from one shaft to another without direct physical contact. It operates based on the principles of magnetism and is designed to transmit rotational power while allowing a degree of misalignment and isolation between the input and output shafts.

The basic components of a magnetic coupling typically include an outer and inner rotor, both containing permanent magnets. The outer rotor is connected to the input shaft, while the inner rotor is connected to the output shaft. These rotors are separated by a non-magnetic containment shell, creating a magnetic air gap between them.

When the input shaft rotates, the magnets on the outer rotor create a magnetic field that passes through the containment shell and induces a corresponding magnetic field in the inner rotor. The interaction between these magnetic fields causes the inner rotor to rotate synchronously with the outer rotor, effectively transferring torque from one shaft to the other.

The key features and functions of magnetic couplings in mechanical power transmission are as follows:

- Non-Contact Power Transmission:

Unlike traditional mechanical couplings that require physical contact between components, a magnetic coupling achieves torque transmission through magnetic fields, enabling a non-contact power transfer.

- Misalignment Compensation:

The magnetic coupling can accommodate a certain amount of misalignment between the input and output shafts. This feature helps prevent excessive forces and wear on the system, improving its overall reliability.

- Isolation and Containment:

The containment shell between the rotors isolates the input and output shafts, making the magnetic coupling ideal for applications where fluid or gas containment is critical. It allows for hermetically sealed connections in pumps, mixers, and other equipment.

- Overload Protection:

In case of sudden overload or jamming in the driven system, the magnetic coupling can slip or disengage, protecting the driving motor and components from damage.

- No Lubrication Requirements:

Since there is no physical contact, magnetic couplings do not require lubrication, reducing maintenance needs and the risk of contamination in sensitive applications.

- No Wear or Friction:

The absence of mechanical contact eliminates wear and friction between the coupling’s components, leading to a longer service life and higher efficiency.

Magnetic couplings find applications in various industries, such as chemical processing, food and beverage, medical devices, and pumps, where leakage prevention, cleanliness, and reliability are essential.

editor by CX 2024-04-19