Product Description

Pass coupling bracelet magnet watch set waterproof vibrator matching pajamas camlock quick release magnetic costume rubber stainless steel galvanized

Application of Pass coupling

Pass coupling is a type of electrical coupling that allows the desired AC signal to pass through while blocking unwanted DC components. This is useful in applications where the AC signal is to be amplified or filtered, but the DC component is not.

Pass coupling is typically used in audio systems, where it is important to preserve the frequency response of the signal. It is also used in radio frequency systems, where it is important to block any unwanted DC components that could interfere with the signal.

There are 2 main types of pass coupling: capacitive coupling and inductive coupling. Capacitive coupling uses a capacitor to block the DC component and pass the AC signal. Inductive coupling uses an inductor to block the DC component and pass the AC signal.

Capacitive coupling is more common than inductive coupling, as it is easier to implement. Inductive coupling is more efficient, but it is also more difficult to implement.

Here are some of the applications of pass coupling:

- Audio systems: Pass coupling is used in audio systems to amplify or filter the AC signal without affecting the DC component. This is important for preserving the frequency response of the signal.

- Radio frequency systems: Pass coupling is used in radio frequency systems to block any unwanted DC components that could interfere with the signal.

- Other: Pass coupling is also used in a variety of other applications, such as power supplies, amplifiers, and filters.

Pass coupling is a versatile and useful technique that can be used in a variety of applications. It is a good choice for applications where it is important to preserve the frequency response of the signal or to block unwanted DC components.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can Magnetic Couplings Be Used in Applications Involving Corrosive or Aggressive Fluids?

Yes, magnetic couplings can be used in applications involving corrosive or aggressive fluids, provided that the coupling is constructed using materials that are compatible with the specific fluid being handled. The ability to use magnetic couplings with corrosive or aggressive fluids depends on the material selection and design of the coupling.

When handling corrosive or aggressive fluids, it’s essential to consider the following factors:

- Material Compatibility:

Select materials for the magnetic coupling that are resistant to the corrosive properties of the fluid. For example, stainless steel, Hastelloy, or certain grades of ceramics are commonly used for components that come into contact with corrosive fluids.

- Hermetic Sealing:

Ensure that the magnetic coupling provides a hermetic seal to prevent fluid leakage. The containment shell and other sealing components must be able to withstand the chemical properties of the aggressive fluid.

- Coatings and Lining:

In some cases, coatings or lining materials can be applied to the coupling’s surfaces that are exposed to the fluid. These coatings can offer additional protection against corrosion and ensure compatibility with aggressive fluids.

- Fluid Temperature and Pressure:

Consider the temperature and pressure of the aggressive fluid, as it may influence the material selection and design of the magnetic coupling. High temperatures or pressures can impact the coupling’s performance and material integrity.

- Fluid Properties:

Understand the specific chemical properties of the aggressive fluid, such as acidity, alkalinity, or reactivity. This information is crucial for selecting appropriate materials and ensuring the coupling can handle the fluid’s properties.

- Manufacturer’s Recommendations:

Consult the magnetic coupling manufacturer for their recommendations on material selection and design considerations for applications involving corrosive or aggressive fluids. They can provide guidance based on their expertise and product specifications.

By carefully considering material compatibility and design factors, magnetic couplings can be successfully used in a wide range of applications involving corrosive or aggressive fluids. These couplings offer advantages such as leak-free operation, reduced maintenance, and the absence of wear-prone components, making them suitable for various industries, including chemical processing, petrochemicals, and pharmaceuticals.

Where Can I Find Reputable Suppliers or Manufacturers of Magnetic Couplings for Specific Engineering Needs?

When searching for reputable suppliers or manufacturers of magnetic couplings, it is essential to consider several factors to meet your specific engineering needs. Here are some valuable resources and steps to help you find reliable suppliers:

- Online Directories:

Online directories, such as ThomasNet, Alibaba, and GlobalSpec, are valuable platforms to search for manufacturers and suppliers of magnetic couplings. These directories provide detailed information about companies, their products, and their capabilities, making it easier to identify potential suppliers.

- Trade Shows and Conferences:

Attending trade shows and engineering conferences related to your industry can be an excellent way to meet and connect with magnetic coupling manufacturers in person. These events provide an opportunity to see product demonstrations, discuss your specific needs, and establish direct contacts with suppliers.

- Industry Associations:

Industry associations and organizations often have a network of members, including suppliers and manufacturers of various engineering components. They may provide valuable recommendations and insights on reputable suppliers of magnetic couplings within your industry.

- Referrals and Recommendations:

Seeking referrals from colleagues or industry professionals who have experience with magnetic couplings can be valuable. Recommendations from trusted sources can save time and help you find reliable suppliers.

- Online Research:

Performing online research and reading customer reviews and testimonials can give you insights into the reputation and reliability of different magnetic coupling suppliers. Look for manufacturers with positive feedback and a track record of delivering quality products.

- Supplier Websites:

Visit the websites of potential magnetic coupling suppliers to learn more about their products, services, and manufacturing capabilities. Look for suppliers with a comprehensive product range, engineering expertise, and a commitment to meeting specific customer requirements.

- Customization Options:

Consider suppliers who offer customization options to meet your specific engineering needs. Magnetic couplings may need to be tailored for particular torque, speed, or environmental requirements, so selecting a manufacturer with the ability to create bespoke solutions is essential.

It is crucial to establish clear communication with potential suppliers, sharing your engineering specifications and expectations. Requesting samples or prototypes, if possible, can also help evaluate the suitability of the magnetic couplings for your specific applications. Ultimately, choosing a reputable and experienced supplier will ensure that you receive high-quality magnetic couplings that meet your engineering needs and contribute to the success of your projects.

Different Types of Magnetic Couplings Used in Various Applications

Magnetic couplings come in different configurations to suit various applications and specific requirements. Some of the common types of magnetic couplings include:

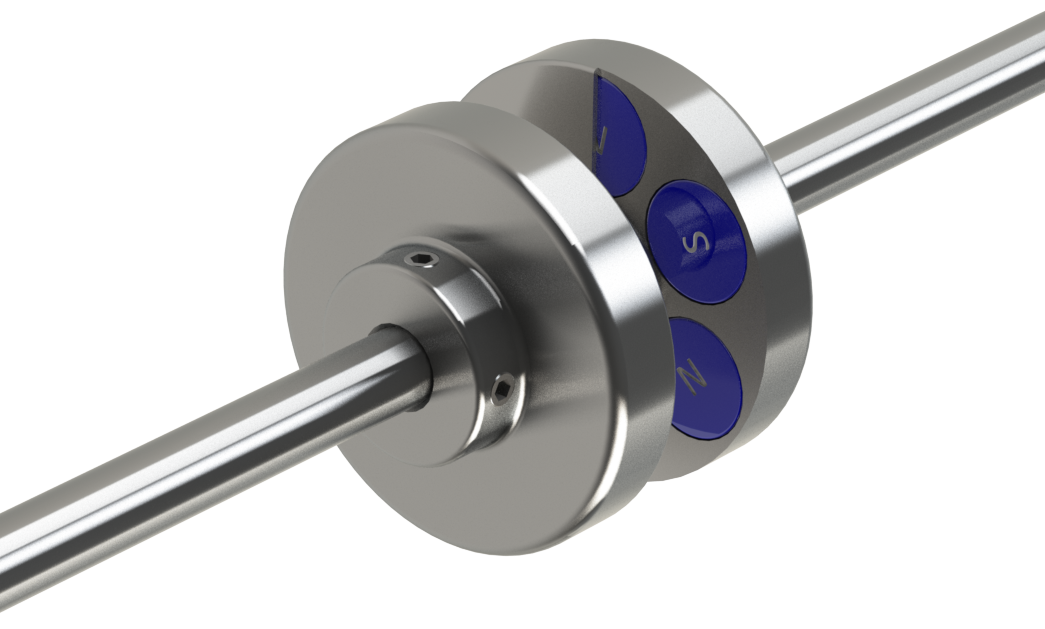

- Standard Magnetic Couplings:

These are the most basic and widely used magnetic couplings. They consist of two rotors with permanent magnets and a containment shell. Standard magnetic couplings are suitable for a wide range of applications, providing non-contact power transmission, misalignment compensation, and isolation between shafts.

- High Torque Magnetic Couplings:

High torque magnetic couplings are designed to transmit higher levels of torque between the input and output shafts. They feature stronger and larger magnets to handle increased power transmission requirements. These couplings are commonly used in heavy-duty industrial applications, such as mixers, agitators, and large pumps.

- Low Torque Magnetic Couplings:

Conversely, low torque magnetic couplings are suitable for applications with lower torque demands. They have smaller and less powerful magnets, making them ideal for applications where precision and efficiency are essential, such as medical devices and laboratory equipment.

- Variable Torque Magnetic Couplings:

Variable torque magnetic couplings provide the ability to adjust the torque transmission level. These couplings can be designed with adjustable magnets or magnetic fields, allowing users to control the torque according to the specific needs of the application. They are used in systems where variable speed and torque are required, such as variable speed pumps and compressors.

- High-Speed Magnetic Couplings:

High-speed magnetic couplings are designed to handle rapid rotations without compromising on efficiency and reliability. They feature special designs and materials to reduce eddy currents and losses associated with high-speed operation. These couplings are commonly used in centrifugal pumps, turbo machinery, and high-speed motors.

- Compact Magnetic Couplings:

Compact magnetic couplings are designed to have a smaller footprint, making them suitable for applications with limited space. They are commonly used in compact pumps, microfluidic systems, and portable devices where space efficiency is crucial.

- Bi-Directional Magnetic Couplings:

Bi-directional magnetic couplings allow power transmission in both directions between the input and output shafts. They are used in applications where bidirectional rotation or periodic reversing of motion is required, such as in mixing applications and reversible pumps.

- Custom Magnetic Couplings:

Manufacturers can also create custom magnetic couplings tailored to specific applications. Custom couplings are designed to meet unique requirements, such as special torque levels, specific environmental conditions, or integration with proprietary systems.

The choice of the magnetic coupling type depends on factors such as torque requirements, speed, space constraints, environmental conditions, and the level of customization needed for the specific application.

editor by CX 2024-05-06