Product Description

Magnetic Motor Coupling Magnetic Coupling Pump Magnetic Couplings

Please send us following information.

1. Motor output power(KW)

2. Motor speed(RPM)

3.Torque of the mangetic coupling

4. Working pressure of the housing(isolation sleeve)

5.Working temperature of magnetic coupling

6. Technical drawing of the output part connector (usually motor)

7. Technical drawing of the input part connector (usually pump)

Specifications of CHINAMFG Magnetic Couplings

Testing Equipment of CHINAMFG Magnetic Couplings

Project of CHINAMFG Magnetic Couplings

Magnetic drive pumps are sealless pumps that use a balanced magnetic field to move fluid through the pump. The drive magnet and inner magnet are separated by a isolation housing, creating a sealless containment. Magnetic coupling pumps will prevent the leakage of fluid, especially dangerous and costly liquids. Due to the simple structure, magnetic pumps save maintenance time of replacing seals and dealing with hazardous leaks.

Magnetic drive pumps are widely used in surface treatment, water treatment, chemical processing, food processing and fluid handling needs in a variety of OEM equipment.

Samarium cobalt magnet is good choice for magnetic coupling pumps, as the maximum operating temperature is up to 350 ºC.

For more information, please refer to greatmagtech or greatmagtech

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Maintenance Requirements for Magnetic Couplings to Ensure Long-Term Performance

Magnetic couplings are designed to be low-maintenance compared to traditional mechanical couplings. However, some maintenance practices can help ensure their long-term performance and reliability. Here are the key maintenance requirements for magnetic couplings:

- Regular Inspection:

Perform regular visual inspections of the magnetic coupling to check for signs of wear, damage, or misalignment. Look for any unusual noises or vibrations during operation, which may indicate a potential issue that requires attention.

- Cleanliness:

Keep the magnetic coupling and surrounding area clean and free from dirt, debris, or contaminants. Foreign particles on the coupling’s surface can affect its magnetic performance and lead to energy losses.

- Lubrication:

Magnetic couplings do not require traditional lubrication since they operate without physical contact. However, some couplings may have bearings or other components that require lubrication. Refer to the manufacturer’s guidelines for specific lubrication requirements.

- Environmental Considerations:

Ensure that the operating environment of the magnetic coupling is within the specified limits provided by the manufacturer. Extreme temperatures, aggressive chemicals, or other harsh conditions can affect the performance and longevity of the coupling.

- Alignment Check:

Periodically check the alignment of the driving and driven shafts. Although magnetic couplings can tolerate some misalignment, ensuring proper alignment will optimize efficiency and reduce stress on the coupling components.

- Torque and Speed Limits:

Adhere to the specified torque and speed limits for the magnetic coupling based on the application requirements. Operating the coupling beyond its rated capacity can lead to premature failure.

- Overload Protection:

If the application involves occasional overloads, consider incorporating overload protection features, such as torque limiters or slip mechanisms, to prevent damage to the coupling and connected equipment.

- Regular Maintenance Schedule:

Establish a regular maintenance schedule based on the manufacturer’s recommendations. Periodic inspections, cleaning, and other maintenance tasks can help identify and address potential issues before they escalate.

- Expert Support:

When in doubt or if encountering any significant issues, seek assistance from the magnetic coupling manufacturer or a qualified engineer. They can provide guidance on maintenance best practices and address any specific concerns related to the coupling’s performance.

By following these maintenance requirements, you can ensure the long-term performance, reliability, and efficiency of the magnetic coupling in your application.

Where Can I Find Reputable Suppliers or Manufacturers of Magnetic Couplings for Specific Engineering Needs?

When searching for reputable suppliers or manufacturers of magnetic couplings, it is essential to consider several factors to meet your specific engineering needs. Here are some valuable resources and steps to help you find reliable suppliers:

- Online Directories:

Online directories, such as ThomasNet, Alibaba, and GlobalSpec, are valuable platforms to search for manufacturers and suppliers of magnetic couplings. These directories provide detailed information about companies, their products, and their capabilities, making it easier to identify potential suppliers.

- Trade Shows and Conferences:

Attending trade shows and engineering conferences related to your industry can be an excellent way to meet and connect with magnetic coupling manufacturers in person. These events provide an opportunity to see product demonstrations, discuss your specific needs, and establish direct contacts with suppliers.

- Industry Associations:

Industry associations and organizations often have a network of members, including suppliers and manufacturers of various engineering components. They may provide valuable recommendations and insights on reputable suppliers of magnetic couplings within your industry.

- Referrals and Recommendations:

Seeking referrals from colleagues or industry professionals who have experience with magnetic couplings can be valuable. Recommendations from trusted sources can save time and help you find reliable suppliers.

- Online Research:

Performing online research and reading customer reviews and testimonials can give you insights into the reputation and reliability of different magnetic coupling suppliers. Look for manufacturers with positive feedback and a track record of delivering quality products.

- Supplier Websites:

Visit the websites of potential magnetic coupling suppliers to learn more about their products, services, and manufacturing capabilities. Look for suppliers with a comprehensive product range, engineering expertise, and a commitment to meeting specific customer requirements.

- Customization Options:

Consider suppliers who offer customization options to meet your specific engineering needs. Magnetic couplings may need to be tailored for particular torque, speed, or environmental requirements, so selecting a manufacturer with the ability to create bespoke solutions is essential.

It is crucial to establish clear communication with potential suppliers, sharing your engineering specifications and expectations. Requesting samples or prototypes, if possible, can also help evaluate the suitability of the magnetic couplings for your specific applications. Ultimately, choosing a reputable and experienced supplier will ensure that you receive high-quality magnetic couplings that meet your engineering needs and contribute to the success of your projects.

What is a Magnetic Coupling and How Does It Function in Mechanical Power Transmission?

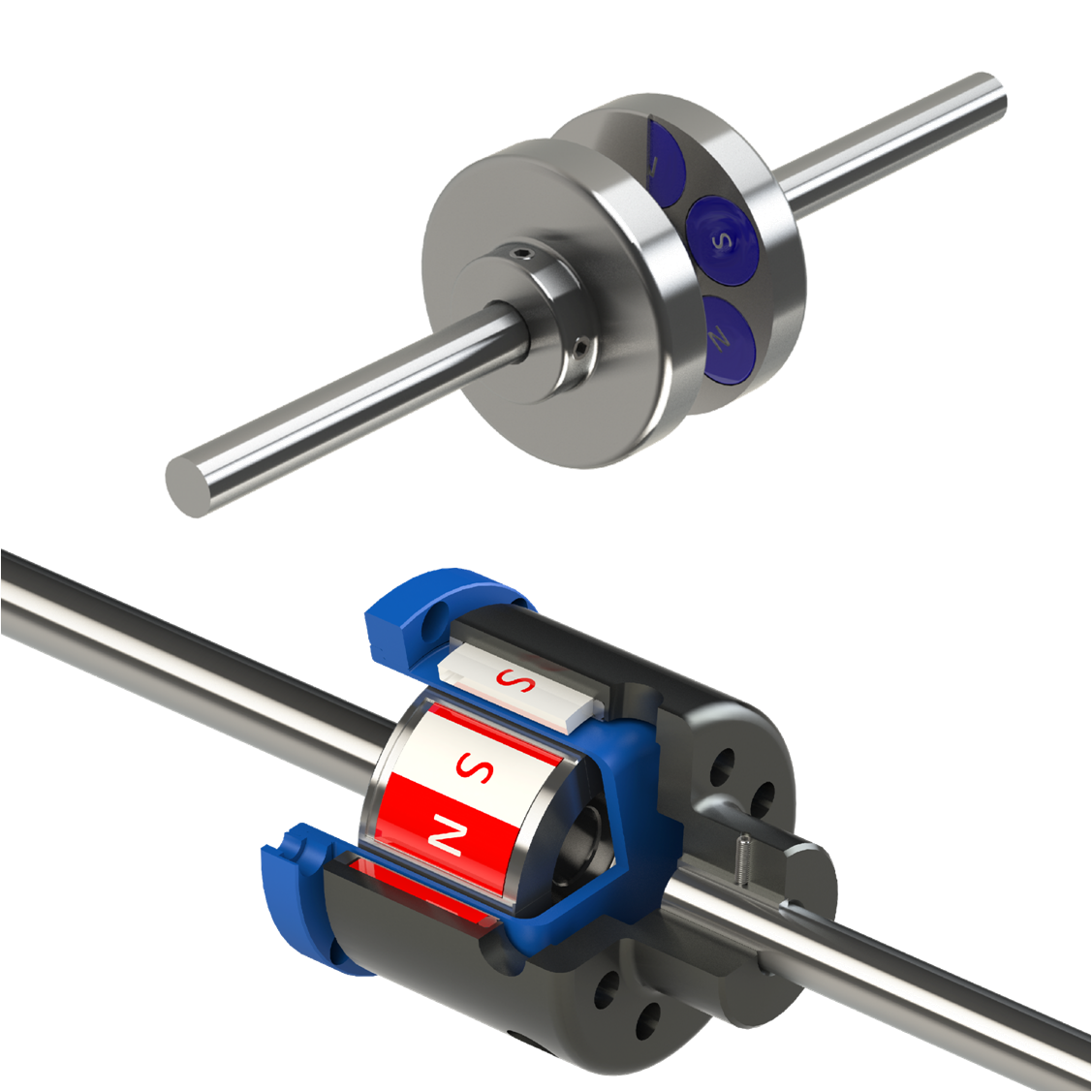

A magnetic coupling is a type of coupling used in mechanical power transmission systems to transfer torque from one shaft to another without direct physical contact. It operates based on the principles of magnetism and is designed to transmit rotational power while allowing a degree of misalignment and isolation between the input and output shafts.

The basic components of a magnetic coupling typically include an outer and inner rotor, both containing permanent magnets. The outer rotor is connected to the input shaft, while the inner rotor is connected to the output shaft. These rotors are separated by a non-magnetic containment shell, creating a magnetic air gap between them.

When the input shaft rotates, the magnets on the outer rotor create a magnetic field that passes through the containment shell and induces a corresponding magnetic field in the inner rotor. The interaction between these magnetic fields causes the inner rotor to rotate synchronously with the outer rotor, effectively transferring torque from one shaft to the other.

The key features and functions of magnetic couplings in mechanical power transmission are as follows:

- Non-Contact Power Transmission:

Unlike traditional mechanical couplings that require physical contact between components, a magnetic coupling achieves torque transmission through magnetic fields, enabling a non-contact power transfer.

- Misalignment Compensation:

The magnetic coupling can accommodate a certain amount of misalignment between the input and output shafts. This feature helps prevent excessive forces and wear on the system, improving its overall reliability.

- Isolation and Containment:

The containment shell between the rotors isolates the input and output shafts, making the magnetic coupling ideal for applications where fluid or gas containment is critical. It allows for hermetically sealed connections in pumps, mixers, and other equipment.

- Overload Protection:

In case of sudden overload or jamming in the driven system, the magnetic coupling can slip or disengage, protecting the driving motor and components from damage.

- No Lubrication Requirements:

Since there is no physical contact, magnetic couplings do not require lubrication, reducing maintenance needs and the risk of contamination in sensitive applications.

- No Wear or Friction:

The absence of mechanical contact eliminates wear and friction between the coupling’s components, leading to a longer service life and higher efficiency.

Magnetic couplings find applications in various industries, such as chemical processing, food and beverage, medical devices, and pumps, where leakage prevention, cleanliness, and reliability are essential.

editor by CX 2024-04-11