Product Description

| Product Name | Cardan Shaft |

| Product Model | SWC-I75A-335+40 |

| Main Material | 35CrMo or 45# Steel |

| Nominal Torque | 500 N.M |

| Normal Length | 335 mm |

| Length Compensation | 40 mm |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How Magnetic Couplings Maintain Efficiency and Reduce Power Loss During Operation

Magnetic couplings offer several features that contribute to their efficiency and help reduce power loss during operation. These characteristics ensure that the majority of the input power is effectively transferred to the driven shaft, leading to enhanced overall system performance. Here’s how magnetic couplings achieve this:

- Non-Contact Power Transmission:

Unlike mechanical couplings that rely on physical contact between components, magnetic couplings operate on the principle of magnetism. There is no friction or mechanical wear, which means there are no energy losses due to rubbing surfaces. The non-contact nature of magnetic couplings significantly reduces power loss and improves efficiency.

- Elimination of Bearings:

In traditional couplings, bearings are often used to support the shafts and minimize friction during rotation. Bearings can contribute to power loss as a portion of the input power is used to overcome bearing friction. In contrast, magnetic couplings do not require bearings for power transmission, further reducing power losses associated with bearing friction.

- Reduced Heat Generation:

Magnetic couplings generate minimal heat during operation. In mechanical couplings, friction between rotating components can lead to heat generation and energy loss. The absence of mechanical contact in magnetic couplings means that the heat generation is significantly lower, preserving energy efficiency.

- Optimized Magnetic Design:

Magnetic couplings are engineered with optimized magnetic designs to minimize eddy current losses. Eddy currents can be induced in conducting materials, such as the containment shell or rotor, leading to power dissipation. Manufacturers carefully design the coupling’s magnetic configuration to reduce eddy current losses and improve overall efficiency.

- Customization for Specific Applications:

Magnetic couplings can be customized for specific applications, allowing for efficient power transmission in diverse operating conditions. Engineers can tailor the coupling’s design, materials, and magnet configurations to match the torque and speed requirements of the application, ensuring maximum efficiency.

- Alignment Flexibility:

Magnetic couplings offer some misalignment tolerance between the driving and driven shafts. This flexibility allows for better alignment under dynamic conditions, minimizing the chances of energy losses due to misalignment-related stresses.

By combining these efficiency-enhancing features, magnetic couplings can maintain high levels of energy transfer from the driving to the driven shaft, resulting in reduced power loss and improved overall system efficiency. These advantages make magnetic couplings suitable for various applications, including pumps, agitators, and other systems where energy efficiency is critical.

Are Magnetic Couplings Suitable for High-Torque or High-Speed Applications in Various Industries?

Yes, magnetic couplings are suitable for high-torque or high-speed applications in various industries, depending on the specific design and material selection. These couplings offer distinct advantages that make them a viable choice for demanding applications with elevated torque and speed requirements.

Here’s how magnetic couplings perform in high-torque and high-speed scenarios:

- High-Torque Applications:

Magnetic couplings can handle high-torque applications efficiently. Neodymium and samarium cobalt magnets, known for their strong magnetic properties, enable magnetic couplings to transmit substantial torque without the need for physical contact. The absence of frictional wear and the robustness of these magnet materials make magnetic couplings well-suited for applications that demand high torque, such as large pumps, agitators, mixers, and heavy-duty industrial machinery.

- High-Speed Applications:

Magnetic couplings can also be designed for high-speed applications. The absence of physical contact between the driving and driven components reduces the risk of mechanical wear and allows magnetic couplings to operate smoothly at high rotational speeds. The magnetic fields effectively transmit power without compromising efficiency or generating excessive heat. Industries such as automotive, aerospace, and precision machinery benefit from magnetic couplings’ ability to maintain performance and reliability at high speeds.

- Advantages in Various Industries:

Magnetic couplings find applications across diverse industries due to their ability to handle high-torque and high-speed requirements. Some notable industries where magnetic couplings are utilized include:

- Chemical and Petrochemical: Magnetic couplings are employed in pumps and agitators, where they prevent fluid leakage and provide a hermetically sealed solution. They are ideal for handling aggressive chemicals and corrosive substances.

- Pharmaceutical: In pharmaceutical processes, magnetic couplings are used in mixers and reactors to prevent contamination and ensure sterile operation.

- Automotive: Magnetic couplings find use in cooling systems, turbochargers, and various engine components to enhance efficiency and reduce maintenance.

- Renewable Energy: In wind turbines, magnetic couplings are utilized to transfer power between the turbine rotor and the generator, offering a maintenance-free and reliable solution.

- Food and Beverage: Magnetic couplings are employed in pumps and mixers for hygienic applications, ensuring no product contamination and meeting food safety standards.

Overall, magnetic couplings demonstrate versatility and effectiveness in high-torque and high-speed applications across multiple industries. Their ability to provide reliable power transmission without mechanical wear and the advantages of hermetic sealing make them an attractive choice for critical systems requiring efficiency, safety, and reduced maintenance.

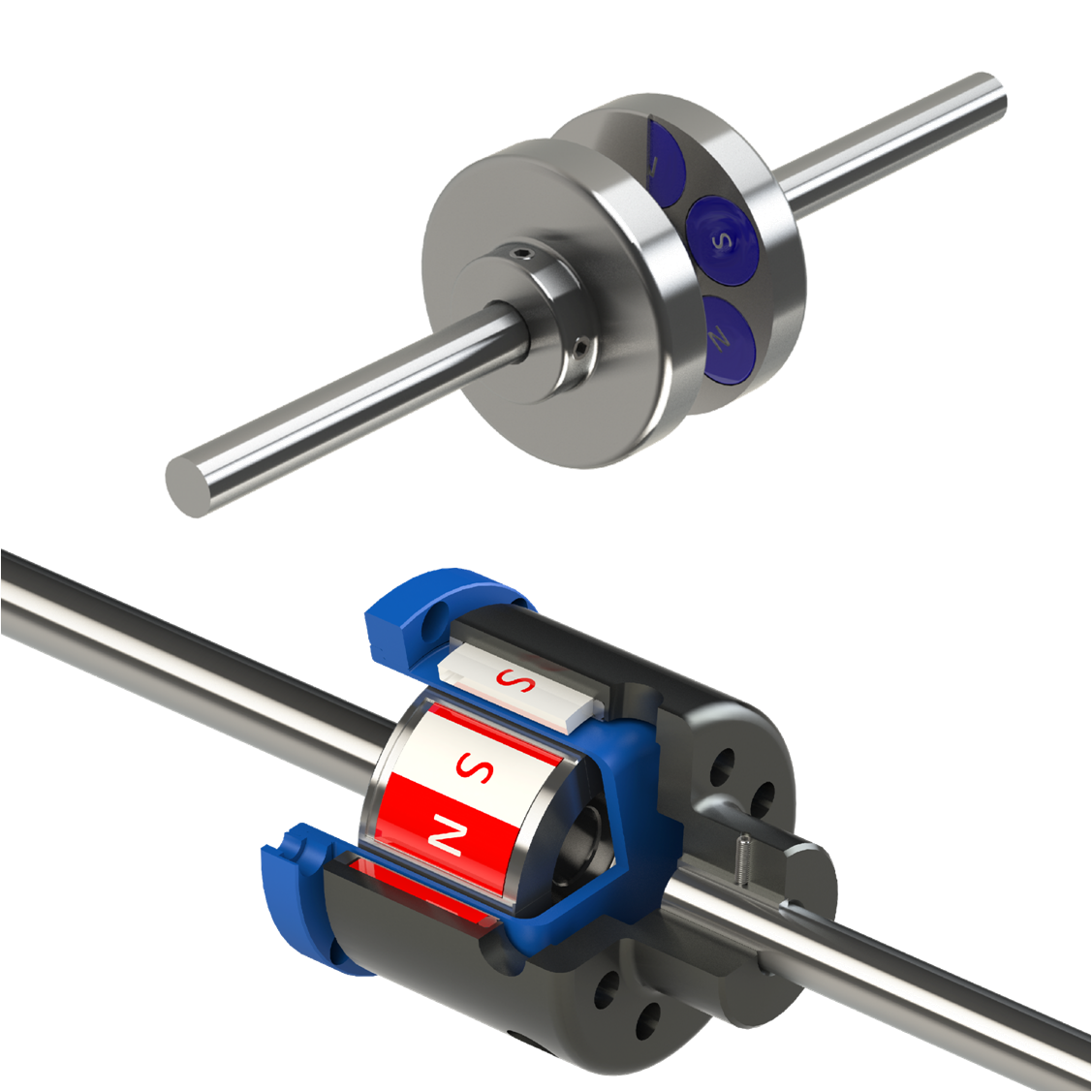

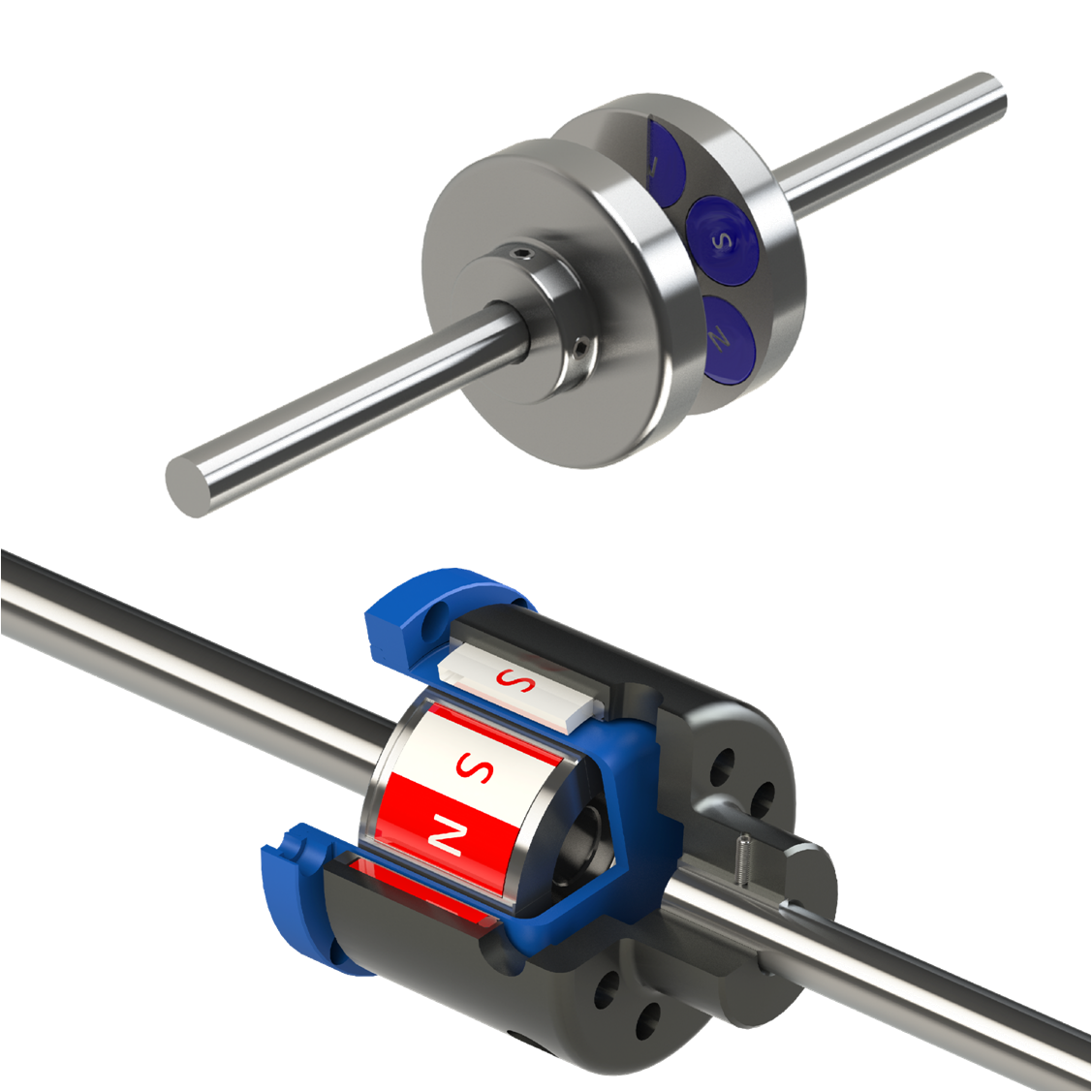

Working Principle of a Magnetic Coupling and Its Advantages Over Traditional Couplings

A magnetic coupling operates on the principle of magnetism to transmit torque from one shaft to another without direct physical contact. It consists of two rotors, an outer rotor connected to the driving shaft and an inner rotor connected to the driven shaft, with a containment shell separating them.

Here’s how a magnetic coupling works:

- Permanent Magnets:

Both the outer and inner rotors contain permanent magnets with alternating poles facing each other. When the driving shaft rotates, the magnets on the outer rotor create a magnetic field.

- Magnetic Induction:

This magnetic field induces a corresponding magnetic field in the inner rotor due to the magnetic permeability of the containment shell. As a result, the inner rotor starts to rotate synchronously with the outer rotor.

- Torque Transmission:

The interaction between the magnetic fields allows torque to be transferred from the driving shaft to the driven shaft without any physical connection. The two shafts remain completely isolated from each other.

The advantages of magnetic couplings over traditional couplings include:

- No Physical Contact:

Magnetic couplings offer non-contact power transmission, eliminating wear and friction that can occur in mechanical couplings. This results in longer service life and reduced maintenance requirements.

- Misalignment Compensation:

Magnetic couplings can tolerate a certain degree of misalignment between the driving and driven shafts. This ability to compensate for misalignment reduces stress on the components and enhances system reliability.

- Hermetic Sealing:

The containment shell in a magnetic coupling provides hermetic sealing between the input and output shafts. This prevents fluid leakage, making magnetic couplings suitable for applications involving hazardous or sensitive fluids.

- Overload Protection:

In case of sudden overloads or blockages in the driven system, a magnetic coupling can slip or disengage, protecting the driving motor and connected components from damage.

- No Lubrication Required:

Since there is no physical contact between components, magnetic couplings do not require lubrication. This feature simplifies maintenance and avoids potential fluid contamination.

Magnetic couplings find applications in various industries, including chemical processing, food and beverage, pharmaceuticals, and power generation, where these advantages are essential for efficient and reliable power transmission.

editor by CX 2024-05-07