Product Description

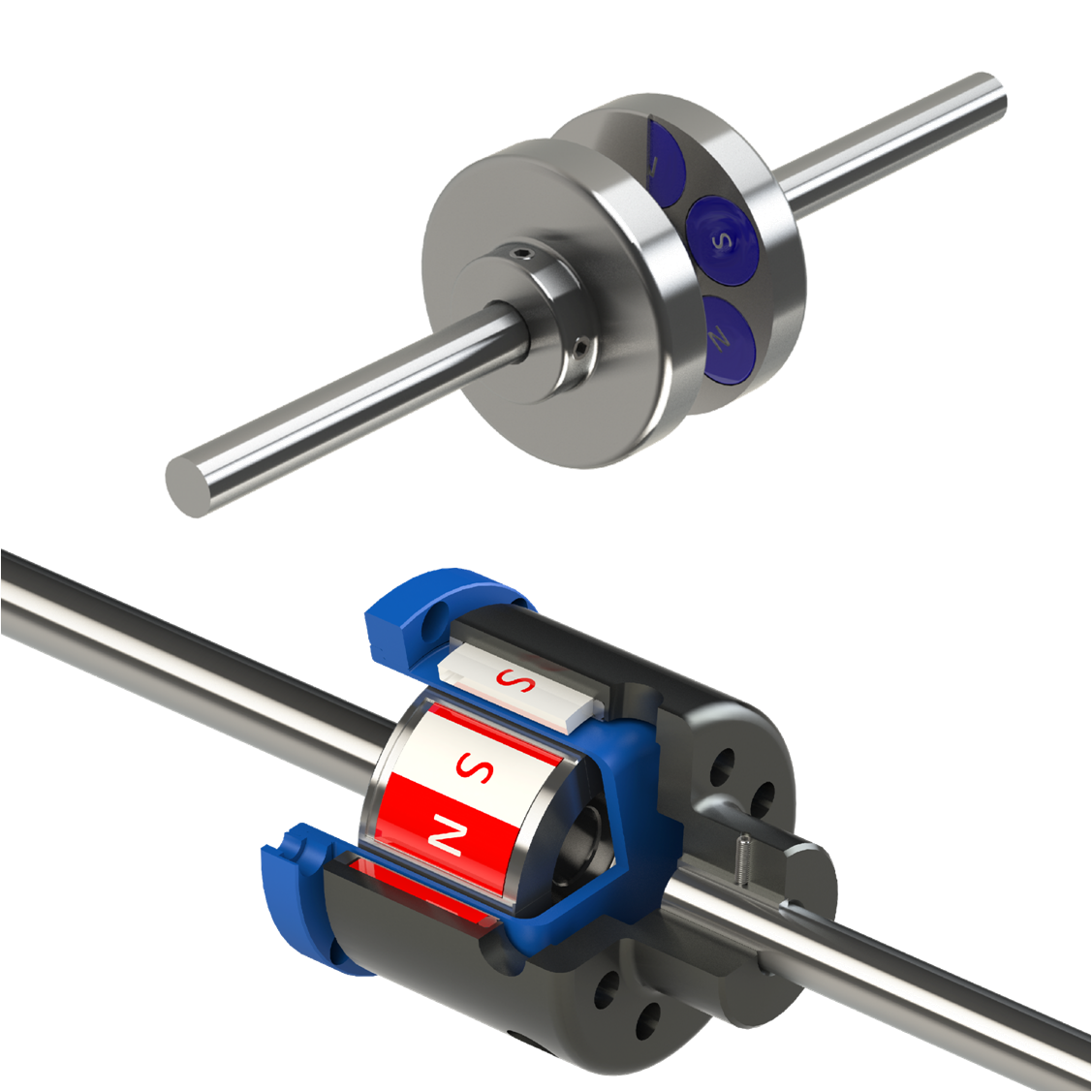

| Product name | Permanent Magnetic Coupling Drive Coupling Magnetic Assembly Supplier |

| Place of Origin | China ZHangZhoug |

| Brand Name | NO |

| Size | Customized Size |

| Coating | Black Epoxy,Ni-Cu-Ni,Zn,etc |

| Material | Neodymium Magnet, hardware |

Services

Sales Service

*Inquiry, and consulting support.

*Sample testing support.

*View our factory.

Buyer Xihu (West Lake) Dis.

In order to give you the best price quickly,please provide the following information:

1.Product size ,grade,coating;

2.Order quantity;

3.Attached the drawings if customized or special shape

4.Any special packing or other requirements.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How Magnetic Couplings Maintain Efficiency and Reduce Power Loss During Operation

Magnetic couplings offer several features that contribute to their efficiency and help reduce power loss during operation. These characteristics ensure that the majority of the input power is effectively transferred to the driven shaft, leading to enhanced overall system performance. Here’s how magnetic couplings achieve this:

- Non-Contact Power Transmission:

Unlike mechanical couplings that rely on physical contact between components, magnetic couplings operate on the principle of magnetism. There is no friction or mechanical wear, which means there are no energy losses due to rubbing surfaces. The non-contact nature of magnetic couplings significantly reduces power loss and improves efficiency.

- Elimination of Bearings:

In traditional couplings, bearings are often used to support the shafts and minimize friction during rotation. Bearings can contribute to power loss as a portion of the input power is used to overcome bearing friction. In contrast, magnetic couplings do not require bearings for power transmission, further reducing power losses associated with bearing friction.

- Reduced Heat Generation:

Magnetic couplings generate minimal heat during operation. In mechanical couplings, friction between rotating components can lead to heat generation and energy loss. The absence of mechanical contact in magnetic couplings means that the heat generation is significantly lower, preserving energy efficiency.

- Optimized Magnetic Design:

Magnetic couplings are engineered with optimized magnetic designs to minimize eddy current losses. Eddy currents can be induced in conducting materials, such as the containment shell or rotor, leading to power dissipation. Manufacturers carefully design the coupling’s magnetic configuration to reduce eddy current losses and improve overall efficiency.

- Customization for Specific Applications:

Magnetic couplings can be customized for specific applications, allowing for efficient power transmission in diverse operating conditions. Engineers can tailor the coupling’s design, materials, and magnet configurations to match the torque and speed requirements of the application, ensuring maximum efficiency.

- Alignment Flexibility:

Magnetic couplings offer some misalignment tolerance between the driving and driven shafts. This flexibility allows for better alignment under dynamic conditions, minimizing the chances of energy losses due to misalignment-related stresses.

By combining these efficiency-enhancing features, magnetic couplings can maintain high levels of energy transfer from the driving to the driven shaft, resulting in reduced power loss and improved overall system efficiency. These advantages make magnetic couplings suitable for various applications, including pumps, agitators, and other systems where energy efficiency is critical.

Where Can I Find Reputable Suppliers or Manufacturers of Magnetic Couplings for Specific Engineering Needs?

When searching for reputable suppliers or manufacturers of magnetic couplings, it is essential to consider several factors to meet your specific engineering needs. Here are some valuable resources and steps to help you find reliable suppliers:

- Online Directories:

Online directories, such as ThomasNet, Alibaba, and GlobalSpec, are valuable platforms to search for manufacturers and suppliers of magnetic couplings. These directories provide detailed information about companies, their products, and their capabilities, making it easier to identify potential suppliers.

- Trade Shows and Conferences:

Attending trade shows and engineering conferences related to your industry can be an excellent way to meet and connect with magnetic coupling manufacturers in person. These events provide an opportunity to see product demonstrations, discuss your specific needs, and establish direct contacts with suppliers.

- Industry Associations:

Industry associations and organizations often have a network of members, including suppliers and manufacturers of various engineering components. They may provide valuable recommendations and insights on reputable suppliers of magnetic couplings within your industry.

- Referrals and Recommendations:

Seeking referrals from colleagues or industry professionals who have experience with magnetic couplings can be valuable. Recommendations from trusted sources can save time and help you find reliable suppliers.

- Online Research:

Performing online research and reading customer reviews and testimonials can give you insights into the reputation and reliability of different magnetic coupling suppliers. Look for manufacturers with positive feedback and a track record of delivering quality products.

- Supplier Websites:

Visit the websites of potential magnetic coupling suppliers to learn more about their products, services, and manufacturing capabilities. Look for suppliers with a comprehensive product range, engineering expertise, and a commitment to meeting specific customer requirements.

- Customization Options:

Consider suppliers who offer customization options to meet your specific engineering needs. Magnetic couplings may need to be tailored for particular torque, speed, or environmental requirements, so selecting a manufacturer with the ability to create bespoke solutions is essential.

It is crucial to establish clear communication with potential suppliers, sharing your engineering specifications and expectations. Requesting samples or prototypes, if possible, can also help evaluate the suitability of the magnetic couplings for your specific applications. Ultimately, choosing a reputable and experienced supplier will ensure that you receive high-quality magnetic couplings that meet your engineering needs and contribute to the success of your projects.

Working Principle of a Magnetic Coupling and Its Advantages Over Traditional Couplings

A magnetic coupling operates on the principle of magnetism to transmit torque from one shaft to another without direct physical contact. It consists of two rotors, an outer rotor connected to the driving shaft and an inner rotor connected to the driven shaft, with a containment shell separating them.

Here’s how a magnetic coupling works:

- Permanent Magnets:

Both the outer and inner rotors contain permanent magnets with alternating poles facing each other. When the driving shaft rotates, the magnets on the outer rotor create a magnetic field.

- Magnetic Induction:

This magnetic field induces a corresponding magnetic field in the inner rotor due to the magnetic permeability of the containment shell. As a result, the inner rotor starts to rotate synchronously with the outer rotor.

- Torque Transmission:

The interaction between the magnetic fields allows torque to be transferred from the driving shaft to the driven shaft without any physical connection. The two shafts remain completely isolated from each other.

The advantages of magnetic couplings over traditional couplings include:

- No Physical Contact:

Magnetic couplings offer non-contact power transmission, eliminating wear and friction that can occur in mechanical couplings. This results in longer service life and reduced maintenance requirements.

- Misalignment Compensation:

Magnetic couplings can tolerate a certain degree of misalignment between the driving and driven shafts. This ability to compensate for misalignment reduces stress on the components and enhances system reliability.

- Hermetic Sealing:

The containment shell in a magnetic coupling provides hermetic sealing between the input and output shafts. This prevents fluid leakage, making magnetic couplings suitable for applications involving hazardous or sensitive fluids.

- Overload Protection:

In case of sudden overloads or blockages in the driven system, a magnetic coupling can slip or disengage, protecting the driving motor and connected components from damage.

- No Lubrication Required:

Since there is no physical contact between components, magnetic couplings do not require lubrication. This feature simplifies maintenance and avoids potential fluid contamination.

Magnetic couplings find applications in various industries, including chemical processing, food and beverage, pharmaceuticals, and power generation, where these advantages are essential for efficient and reliable power transmission.

editor by CX 2024-03-14