Product Description

Coupling Shafts Pump Couplings Power Transmission Couplings

Introduction of Power Transmission Couplings

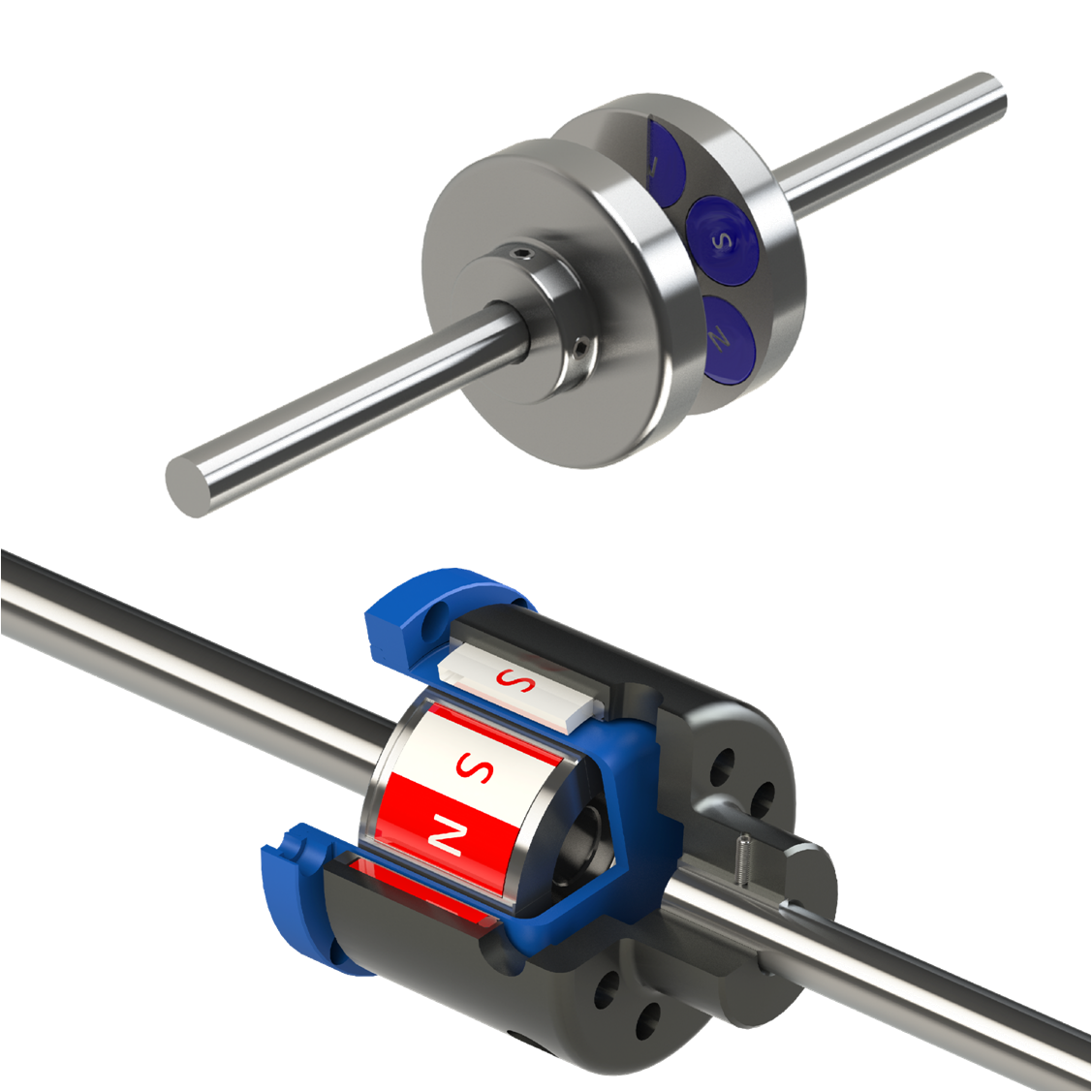

As 1 of the newly-developed coupling, magnetic coupling is for transmitting torque by magnetic components. It is ideal for torque transmitting between the hazardous inside and outside parts of the high pressure vessel. Magnetic coupling is a key component to achieve non-contact torque transmission and complete no-leakage.

Magnetic coupling is composed of outer magnetic rotor, inner magnetic rotor and isolation cover. The outer magnetic rotor is connected with motor and exposed outside. The inner magnetic rotor and the pump shaft are integrated together, and the whole rotor is contained in the pump housing and the spacer sleeve and is immersed in the transmission medium.

The spacer sleeve, which is between the inner and outer rotor, is fixed on the pump housing so that the pump housing and the isolation sleeve to be a mutually connected and completely sealed chamber.

Magnets are closely arranged along the circumferential direction on the outer cylindrical surface of inner rotor and inner cylindrical surface of outer rotor, forming a combination of push-pull magnetic circuit.

Dimensions of CHINAMFG Pump Couplings

Specification Data Required for Magnetic Coupling Quotation

Motor output power(KW)

Motor speed(RPM)

Torque of the magnetic coupling

Working pressure of the housing (isolation sleeve)

Working temperature of magnetic coupling

Connector size of the output part (usually motor)

Technical drawing/Mounting Dimensions of the input part (usually pump)

Operating Process Attentions

Magnetic coupling is the middle connecting part of each motion mechanism, it has a direct impact on the normal operation of each motion mechanism.

Therefore, care must be taken when using:

Magnetic couplings are not allowed to have more than the specified axis skew and radial displacement. If the problem is serious, the transmission capacity will decrease and eventually lead to the transmission parts scrapped.

A: The axis skew can cause friction between inner/outer rotor and spacer sleeve, finally lead to rotors and isolation sleeve stuck and scrapped.

B: Problems in the installation of the inner/outer rotor bearing finally lead to rotors and isolation sleeve stuck and scrapped.

C: Magnetic coupling external accessories such as the installation of the rack or bolt must not have loose defects.

D: Be sure to clean up the metal debris and note that there is no metal debris on the inner/outer rotor surface.

E: After installing, manually rotate the motor wind blade to make sure that the unit is functioning smoothly and free of blocking phenomenon.

F: Bearings should be lubricated periodically, usually 2-3 months, in order to avoid serious consequences caused by severe wear.

G: The key of the magnetic coupling should cooperate closely without loose.

Project of CHINAMFG Magnetic Couplings

Magnetic drive pumps are sealess pumps that use a balanced magnetic field to move fluid through the pump. The drive magnet and inner magnet are separated by a isolation housing, creating a sealless containment. Due to the simple structure, magnetic pumps save maintenance time of replacing seals and dealing with hazardous leaks.

Magnetic drive pumps are widely used in surface treatment, water treatment, chemical processing, food processing and fluid handling needs in a variety of OEM equipment.

GME core values

Customer Care

Quality is our life. Customer satisfaction is our CHINAMFG pursuit. Everything we do at CHINAMFG is driven by an unyielding passion for CHINAMFG in identifying and delivering solutions that exceed expectations.

Innovation

In today’s fast-developing global economy, innovation is critical to a company’s survival. We anticipate and adapt to changing for continuous improvement.

Co-Prosperity

A business cannot be successful unless it creates prosperity and opportunity for others. We have a dream–customers could win more through our Great Service; we have a dream–GME members could realize their own dreams while striving for CHINAMFG Dream.

Social Responsibility

Sustainability isn’t only important for people and the planet, but also is vital for business success. We are environmentally responsible and drive to sustainability. And we should do something for our better future.

For more information, please refer to greatmagtech or greatmagtech /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Are there any Safety Considerations or Guidelines for Using Magnetic Couplings in Hazardous Environments?

Yes, when using magnetic couplings in hazardous environments, there are several safety considerations and guidelines that should be followed to ensure the safety of personnel and equipment. Hazardous environments may involve flammable, explosive, or corrosive substances, and it’s crucial to address potential risks. Here are the safety considerations and guidelines:

- Material Selection:

Choose magnetic couplings constructed from materials that are compatible with the hazardous substances present in the environment. For example, some chemicals may be corrosive, so the coupling’s materials must resist corrosion to maintain integrity.

- Sealing:

Ensure that the magnetic coupling provides a hermetic seal to prevent fluid leakage and the release of hazardous substances into the environment. The containment shell should be designed to withstand the pressures and temperatures of the specific application.

- Explosion-Proof:

In environments where flammable or explosive substances are present, consider using explosion-proof magnetic couplings. These couplings are designed to prevent the ignition of flammable gases or vapors in the event of a fault.

- Compliance with Regulations:

Ensure that the magnetic coupling meets all relevant safety and industry standards for hazardous environments. Compliance with regulations, such as ATEX or IECEx, is essential to ensure the coupling’s suitability for use in specific hazardous locations.

- Environmental Conditions:

Evaluate the environmental conditions of the hazardous area, including temperature, pressure, and chemical exposure. The magnetic coupling should be rated and designed to withstand the specific conditions of the environment.

- Grounding:

Properly ground the magnetic coupling and the associated equipment to dissipate any static charges and prevent sparks that could ignite flammable substances.

- Installation and Maintenance:

Follow the manufacturer’s recommended installation and maintenance procedures to ensure the magnetic coupling functions correctly in the hazardous environment. Regular inspections and maintenance are essential to identify and address any potential issues.

- Training and Awareness:

Provide training to personnel working in the hazardous area about the risks associated with magnetic couplings and the proper procedures to follow in case of any abnormalities or emergencies.

It is crucial to consult with experts or engineers experienced in hazardous environments to ensure that the magnetic coupling is appropriately selected and installed for the specific application. Following these safety considerations and guidelines will help mitigate risks and ensure safe operation in hazardous environments.

How do Magnetic Couplings Contribute to the Overall System Reliability and Prevent Mechanical Wear?

Magnetic couplings offer several advantages that contribute to the overall system reliability and prevent mechanical wear. These benefits are a result of their non-contact power transmission principle and unique design features. Here’s how magnetic couplings achieve this:

- No Physical Contact:

Magnetic couplings operate without any physical contact between the driving and driven components. Unlike traditional mechanical couplings that rely on friction and wear-prone components, magnetic couplings use magnetic fields to transfer torque and power. This absence of physical contact eliminates mechanical wear and reduces the need for regular maintenance and replacement of wearing parts.

- Hermetic Sealing:

Magnetic couplings often feature a hermetic sealing design that prevents fluid leakage. The driving and driven components are separated by a sealed containment shell, which ensures that there is no direct exposure to the environment or the fluid being handled. This hermetic sealing not only prevents leakage but also protects sensitive components from contamination and external influences, enhancing the overall system reliability.

- Reduced Friction Losses:

Since there is no physical contact between the coupling’s components, magnetic couplings experience minimal friction losses during operation. The reduction in frictional forces translates to higher efficiency and lower energy consumption compared to traditional couplings with sliding or rolling elements.

- Tolerance to Misalignment:

Magnetic couplings can accommodate a certain degree of misalignment between the driving and driven components. This misalignment tolerance helps to minimize stress on the coupling and connected equipment, reducing the risk of premature wear or failure in situations where perfect alignment may not be achievable or maintained over time.

- Overload Protection:

Some magnetic couplings are designed with built-in overload protection features. In case of excessive torque or sudden overloads, these couplings can disengage or slip, preventing damage to the coupling and the connected machinery. This overload protection contributes to the long-term reliability of the system by avoiding potential catastrophic failures.

- No Lubrication Required:

Unlike many traditional mechanical couplings that need regular lubrication to reduce friction and wear, magnetic couplings do not require lubrication. The absence of lubricants simplifies maintenance and eliminates the risk of lubricant contamination in sensitive applications.

Overall, magnetic couplings offer a reliable and efficient solution for various applications, especially in industries where the prevention of mechanical wear, fluid leakage, and frequent maintenance are essential considerations. Their non-contact design, hermetic sealing, and tolerance to misalignment make them an attractive choice for critical systems that demand high reliability and performance.

What is a Magnetic Coupling and How Does It Function in Mechanical Power Transmission?

A magnetic coupling is a type of coupling used in mechanical power transmission systems to transfer torque from one shaft to another without direct physical contact. It operates based on the principles of magnetism and is designed to transmit rotational power while allowing a degree of misalignment and isolation between the input and output shafts.

The basic components of a magnetic coupling typically include an outer and inner rotor, both containing permanent magnets. The outer rotor is connected to the input shaft, while the inner rotor is connected to the output shaft. These rotors are separated by a non-magnetic containment shell, creating a magnetic air gap between them.

When the input shaft rotates, the magnets on the outer rotor create a magnetic field that passes through the containment shell and induces a corresponding magnetic field in the inner rotor. The interaction between these magnetic fields causes the inner rotor to rotate synchronously with the outer rotor, effectively transferring torque from one shaft to the other.

The key features and functions of magnetic couplings in mechanical power transmission are as follows:

- Non-Contact Power Transmission:

Unlike traditional mechanical couplings that require physical contact between components, a magnetic coupling achieves torque transmission through magnetic fields, enabling a non-contact power transfer.

- Misalignment Compensation:

The magnetic coupling can accommodate a certain amount of misalignment between the input and output shafts. This feature helps prevent excessive forces and wear on the system, improving its overall reliability.

- Isolation and Containment:

The containment shell between the rotors isolates the input and output shafts, making the magnetic coupling ideal for applications where fluid or gas containment is critical. It allows for hermetically sealed connections in pumps, mixers, and other equipment.

- Overload Protection:

In case of sudden overload or jamming in the driven system, the magnetic coupling can slip or disengage, protecting the driving motor and components from damage.

- No Lubrication Requirements:

Since there is no physical contact, magnetic couplings do not require lubrication, reducing maintenance needs and the risk of contamination in sensitive applications.

- No Wear or Friction:

The absence of mechanical contact eliminates wear and friction between the coupling’s components, leading to a longer service life and higher efficiency.

Magnetic couplings find applications in various industries, such as chemical processing, food and beverage, medical devices, and pumps, where leakage prevention, cleanliness, and reliability are essential.

editor by CX 2024-03-02